-

Help Support Hardline Crawlers :

GM Water pump neck

- Thread starter Beerj

- Start date

85toyo

Well-Known Member

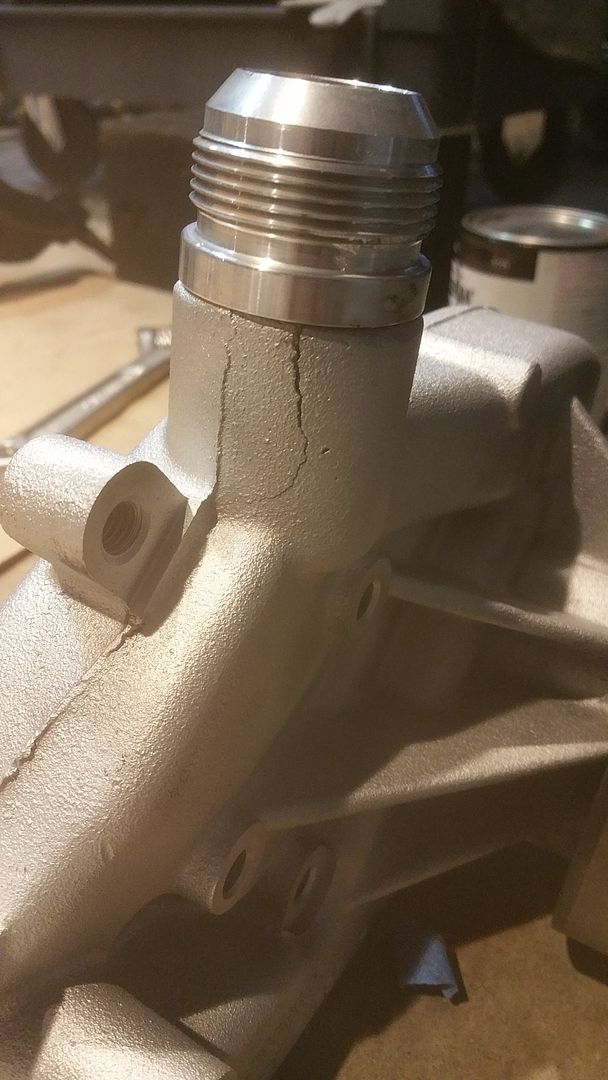

I hope you have better luck than I did. I couldn't get the water pump to sit flat on the press and it got in there crooked. Never could get it straightened out. Wouldn't go in any further or come out. Just cut it out of the pump last night. Reckon I'm going to order a weld on fitting and take it to a buddy.

Beerj

Sonzabitches!

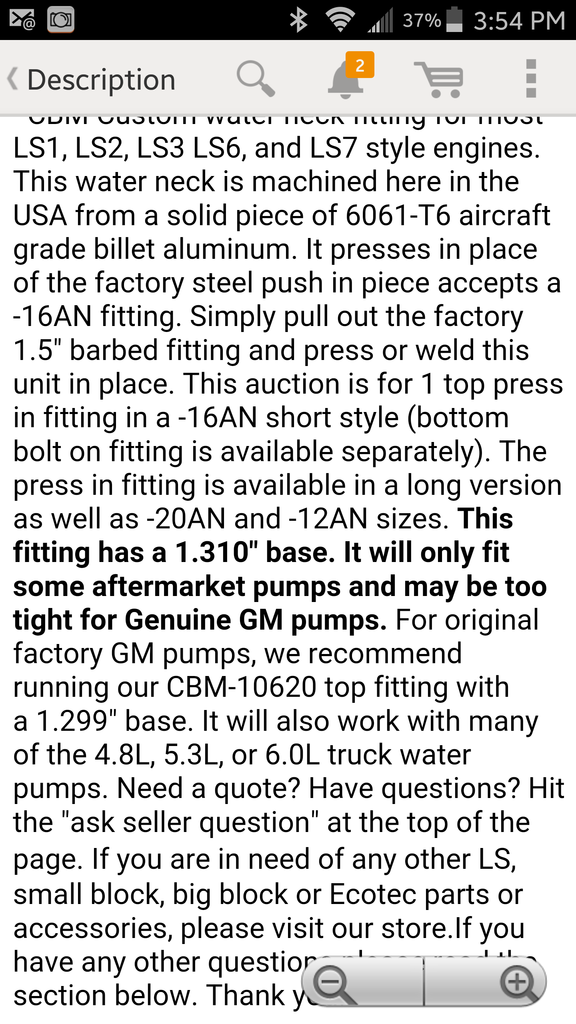

Damn, not the answer I was expecting. Do you know which part # you got? I remember them having 2 different sizes.

85toyo

Well-Known Member

Beerj

Sonzabitches!

pholmann

Well-Known Member

Use some green lock-title bearing set. You'll have to buy another one if the water pump goes bad but it shouldn't come out or leak.

85toyo

Well-Known Member

Beerj said:

Damn I got screwed on that haha. I ordered it from Kryptonite Kustoms and they had one for car pumps and one for truck pumps with no description. Didn't even say it was a CBM and they charged me $50

Kinda my fault but google wouldn't find another source at the time.

Kinda my fault but google wouldn't find another source at the time.Beerj

Sonzabitches!

Yeah, I saw that. Actually if it wasn't for that I probably would've just went in dry.patooyee said:You probably already know this but the stock water neck has some sort of glue / epoxy.

pholmann said:Use some green lock-title bearing set. You'll have to buy another one if the water pump goes bad but it shouldn't come out or leak.

Cool, I'll see if I can find some. Kinda pains me to keep modifying stock parts since they'll need done again if they get replaced but this one hopefully won't be too bad.

85toyo said:Damn I got screwed on that haha. I ordered it from Kryptonite Kustoms and they had one for car pumps and one for truck pumps with no description. Didn't even say it was a CBM and they charged me $50Kinda my fault but google wouldn't find another source at the time.

Lol. Someone had a link to kryptonite kustoms on here a little while ago. Once I daw they carried CBM products I knew ebay would be cheaper. Hopefully I can get this together easily.

85toyo

Well-Known Member

How is the fit on yours?

Beerj

Sonzabitches!

I haven't pressed it in yet. Still trying to locate the magical green loctite locally. As soon as I get some free time I'll pull the pump and clean up the glue residue from the stock neck. There appears to be about 10 thousandths interference. I think it dropped to about 7 after I froze the bung. But right now it doesn't drop in at all by hand.

pholmann

Well-Known Member

You could probably use some pipe dope too.

Beerj

Sonzabitches!

Pipe dope I have. I even tossed around the idea of some 2 part epoxy. Honesty, I'm more worried about leaks than keeping it in there. It's gonna be so tight I don't see it going anywhere.

pholmann

Well-Known Member

Pipe dope or epoxy should work then

Beerj

Sonzabitches!

Roger that! Once the boy goes down for a nap this afternoon I'll see if I can cram it together.

That seems a little to much on that press fit.... Rule of thumb is normally .001 per inch in diameter give or take depending on material so you might want to look into before you start and get it stuck and have to ruin it or it might go in no problem haha

pholmann

Well-Known Member

You can always get a little hone to take some out of the water pump if you don't have access to a lathe to take it off the fitting.

Beerj

Sonzabitches!

jccarter1 said:That seems a little to much on that press fit.... Rule ofjccarter1 said:That seems a little to much on that press fit.... Rule of thumb is normally .001 per inch in diameter give or take depending on material so you might want to look into before you start and get it stuck and have to ruin it or it might go in no problem hahaMan, wish I would've checked this thread again before I started.pholmann said:You can always get a little hone to take some out of the water pump if you don't have access to a lathe to take it off the fitting.

Figured I'd clean it up first.

I got the works situated on the press nice an square, dabbed some dope and went at it. It was sliding right in no problem about half way and then pop!

:'(

pholmann

Well-Known Member

Oops