Alpine4x4

Well-Known Member

No I didn't buy a ****ing Jeep:flipoff:

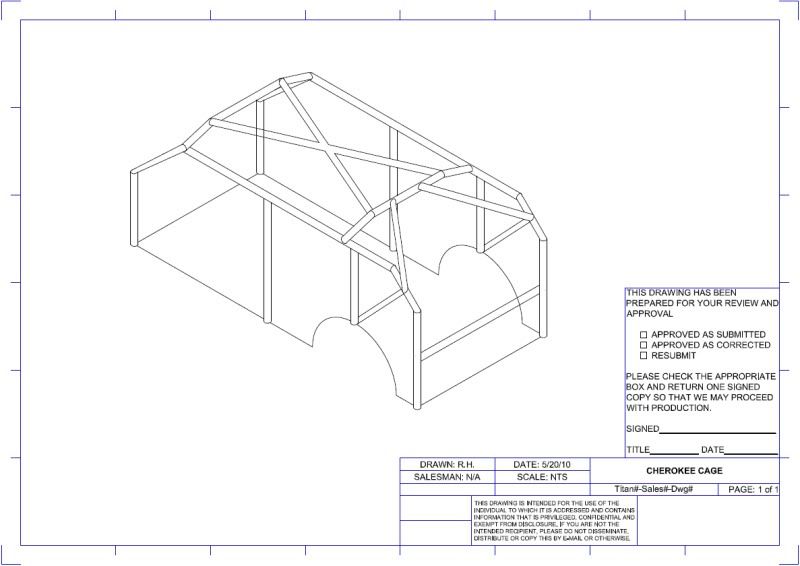

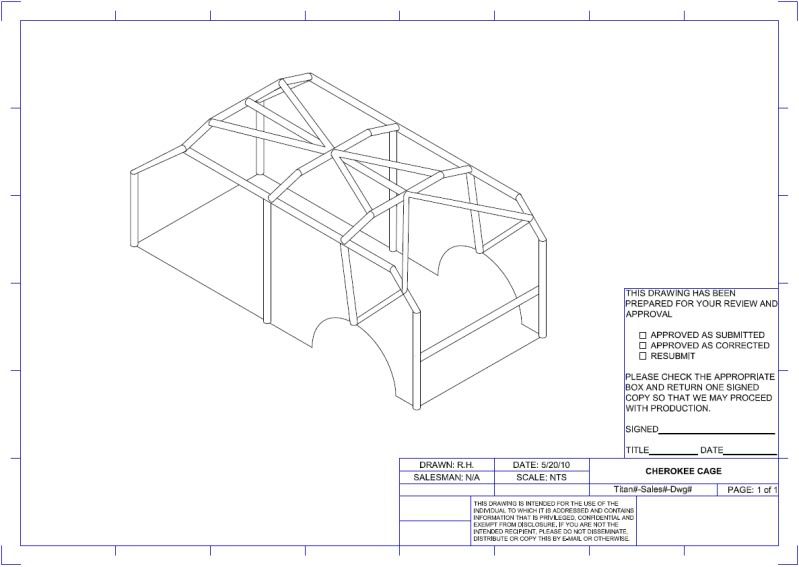

My buddy chopped the back off of his 4 door cherokee and we're now in the process of installing a cage. Was looking for pictures, designs, ideas, tips, anything that can help us along the way. This is our first cage build and I know triangulation is key so I'm trying to integrate it in as much as possible where needed without looking cluttered.

Thanks.

My buddy chopped the back off of his 4 door cherokee and we're now in the process of installing a cage. Was looking for pictures, designs, ideas, tips, anything that can help us along the way. This is our first cage build and I know triangulation is key so I'm trying to integrate it in as much as possible where needed without looking cluttered.

Thanks.