wizzo

Well-Known Member

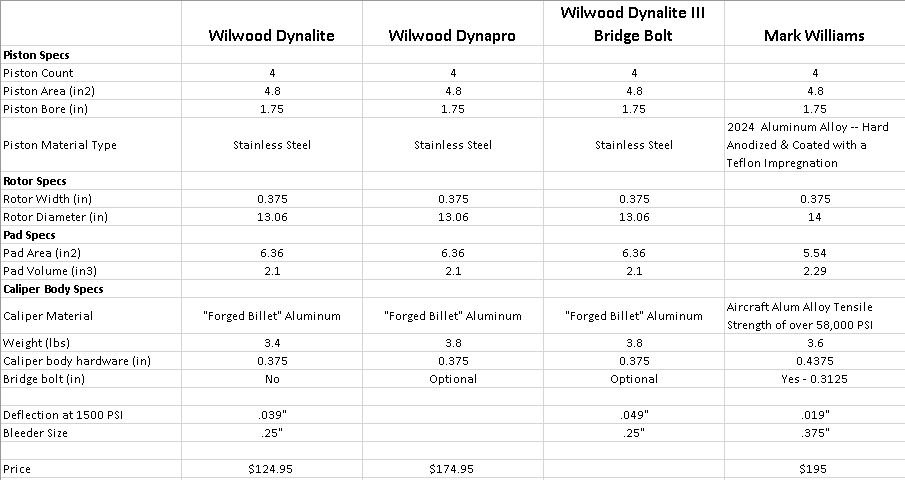

There has been some discussion in the 14 bolt front axle build thread. So I wanted to make a separate thread as to not dilute the other with only brake caliper info.

Numbers on a chart don't necessarily tell the whole story.

The Mark Williams caliper is made from aircraft grade aluminum alloy with a tensile strength of over 58,000PSI. The caliper material along with the 7/16" fasteners and 5/16" center bridge bolt is KEY! Bridge strength is crucial when it comes to holding and stopping power. Caliper deflection causes the pad to no longer make full contact with the rotor. The more contact you lose, the less braking and holding power you have. The deflection difference between the MW caliper and standard dynalite that most guys are running is roughly 49%.

Holding power for the MW caliper on the 14" rotor, with MW 81030 brake pads at 1200 psi is 1434 ft. lbs. of torque. These numbers are on a cold disc. When the heat increases, the torque values increase quite a bit. Testing has shown 24% increase in torque at 425 degrees Fahrenheit.

Mark Williams brake pads are made from a sindered iron compound. This 3410F compound gives you the best of both stopping power and rotor life.

The pistons MW uses are made from 2024 aluminum alloy. They are hard anodized and coated with a Teflon impregnation. This combination of material used and Teflon impregnation, ensure parts move as they should without galling or binding. Heat testing has shown stainless steel pistons do not expand and contract at the same rate as the aluminum housing. This allows the opportunity for brake dust and debris to collect and piston binding to occur.

All Mark Williams components are made in the USA!

This is purely some data and specific differences. Will the Wilwood calipers work? Yes, you're not going to kill a bus full of nuns if you're running the Wilwood caliper. I've ran them for the past 5+ years and the calipers have flexed and the pads have worn unevenly since day one.

Numbers on a chart don't necessarily tell the whole story.

The Mark Williams caliper is made from aircraft grade aluminum alloy with a tensile strength of over 58,000PSI. The caliper material along with the 7/16" fasteners and 5/16" center bridge bolt is KEY! Bridge strength is crucial when it comes to holding and stopping power. Caliper deflection causes the pad to no longer make full contact with the rotor. The more contact you lose, the less braking and holding power you have. The deflection difference between the MW caliper and standard dynalite that most guys are running is roughly 49%.

Holding power for the MW caliper on the 14" rotor, with MW 81030 brake pads at 1200 psi is 1434 ft. lbs. of torque. These numbers are on a cold disc. When the heat increases, the torque values increase quite a bit. Testing has shown 24% increase in torque at 425 degrees Fahrenheit.

Mark Williams brake pads are made from a sindered iron compound. This 3410F compound gives you the best of both stopping power and rotor life.

The pistons MW uses are made from 2024 aluminum alloy. They are hard anodized and coated with a Teflon impregnation. This combination of material used and Teflon impregnation, ensure parts move as they should without galling or binding. Heat testing has shown stainless steel pistons do not expand and contract at the same rate as the aluminum housing. This allows the opportunity for brake dust and debris to collect and piston binding to occur.

All Mark Williams components are made in the USA!

This is purely some data and specific differences. Will the Wilwood calipers work? Yes, you're not going to kill a bus full of nuns if you're running the Wilwood caliper. I've ran them for the past 5+ years and the calipers have flexed and the pads have worn unevenly since day one.

Last edited: