Matze1989

Well-Known Member

Hi hardline community,

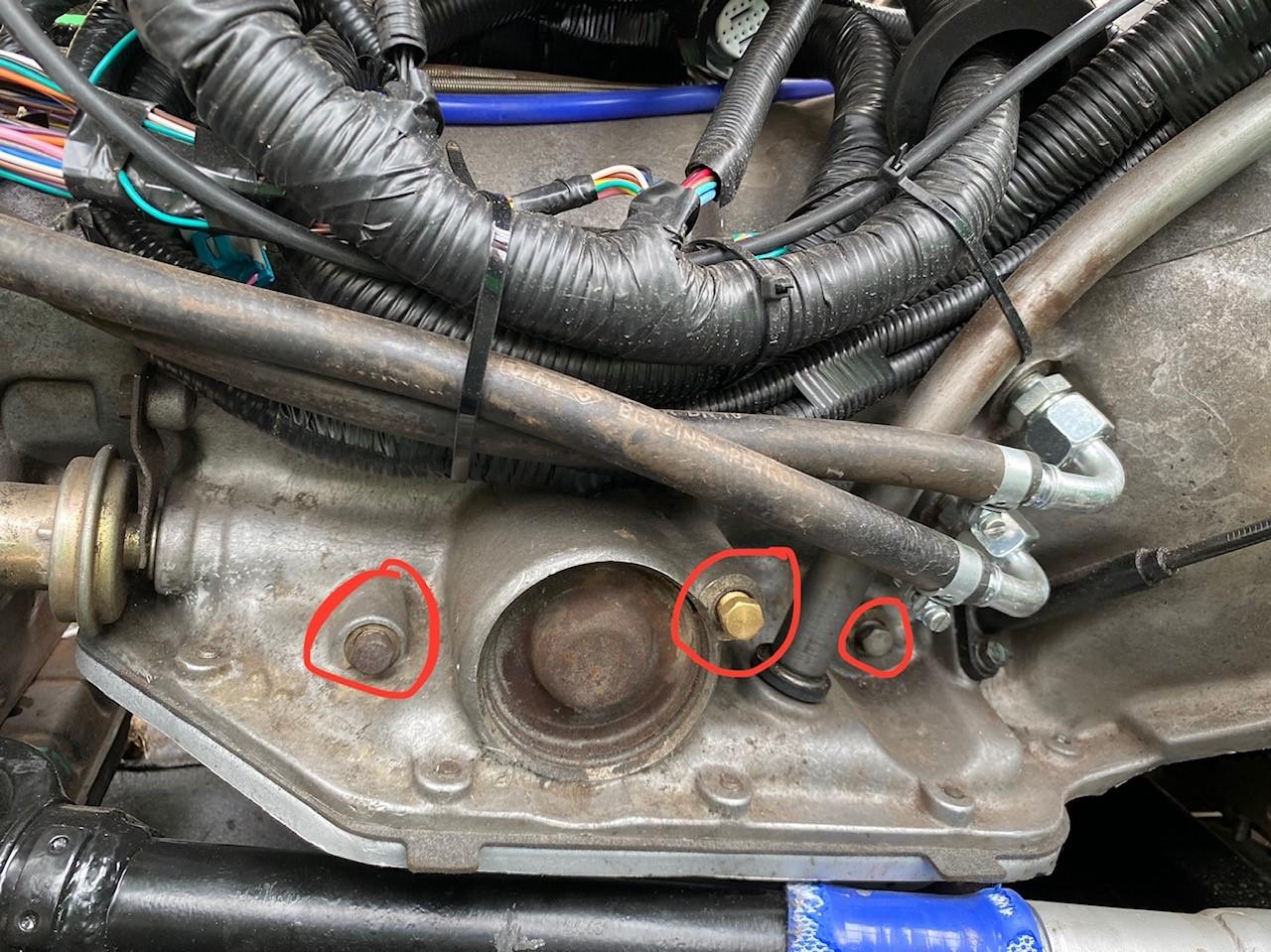

Matthias here from germany. We just updated our "Avalanche" Buggy to LM7 5.3 V8 and TH350 transmission. I really need to monitor trans oil temperature in some races and i would like to fit a sensor (the best would be 1/8 NPT thread) somewhere into the transmission or at the beginning of the oil line to the cooler. Is any of the marked bolts able to go out and fit a sensor? My TH350 knowledge is basically zero and i would appreciate any help. Thank you!

By the way: Yes driveshaft fitment is veeeeery close

Regards,

Matthias Kocher

Matthias here from germany. We just updated our "Avalanche" Buggy to LM7 5.3 V8 and TH350 transmission. I really need to monitor trans oil temperature in some races and i would like to fit a sensor (the best would be 1/8 NPT thread) somewhere into the transmission or at the beginning of the oil line to the cooler. Is any of the marked bolts able to go out and fit a sensor? My TH350 knowledge is basically zero and i would appreciate any help. Thank you!

By the way: Yes driveshaft fitment is veeeeery close

Regards,

Matthias Kocher