archer66

Well-Known Member

For those of you who lurk around FSB this'll be a repost

Had a little fun over the weekend...

Started with this...

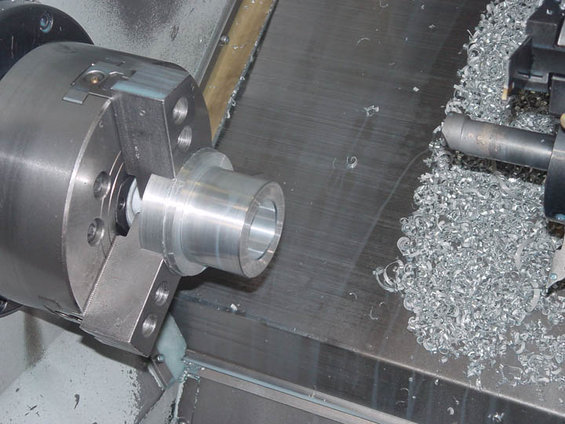

after cleaning it up and whacking a chunk off...

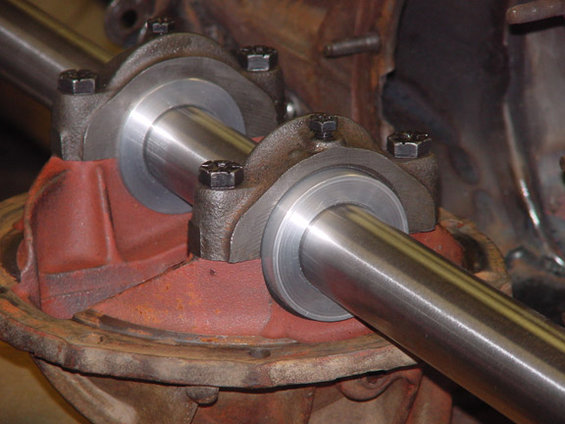

Add some 1/4" plate

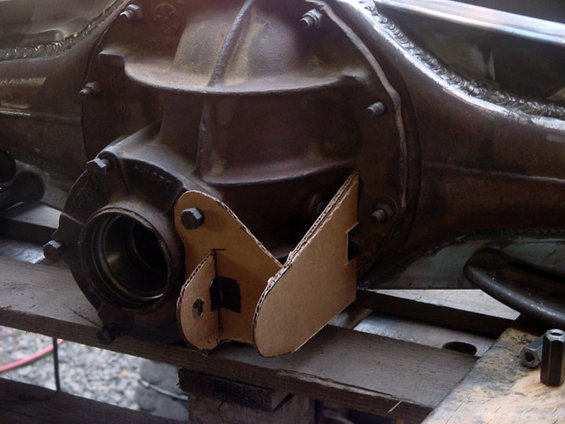

a little grinding and welding

Now some gussets/trusses....

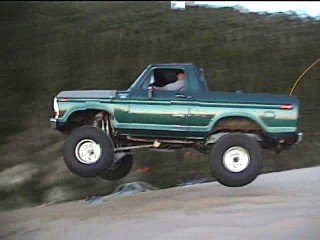

And I've gotta get a picture in here of the reason for all this ....:redneck:

I still need to build the mount points for the center traction bar and fab it and its x-member....

I'm also going to build a flush "bung" for draining the rear housing and set the gears up on my Detroit. Should be done with that this coming weekend.

And yes I plan on shaving the shock mounts...caught some greef over that already. I'm working on a quad shock set up just haven't settled on a design yet...

Had a little fun over the weekend...

Started with this...

after cleaning it up and whacking a chunk off...

Add some 1/4" plate

a little grinding and welding

Now some gussets/trusses....

And I've gotta get a picture in here of the reason for all this ....:redneck:

I still need to build the mount points for the center traction bar and fab it and its x-member....

I'm also going to build a flush "bung" for draining the rear housing and set the gears up on my Detroit. Should be done with that this coming weekend.

And yes I plan on shaving the shock mounts...caught some greef over that already. I'm working on a quad shock set up just haven't settled on a design yet...