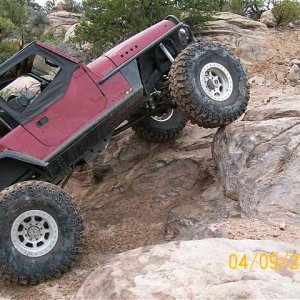

Rockwells607

Well-Known Member

so i wanna make a set of aluminum outer beadlock rings, whats everyone using? how thick and what grade aluminum? prolly draw a sketch on a napkin and give it to the programmer...he sits behind his computer drawing work crap all day, im sure he would love a fun little project and i will mill em out

Just Kidding

Just Kidding