matth_85

Well-Known Member

- Joined

- Jul 31, 2011

- Messages

- 1,206

So, after cleaning the buggy from Harlan I noticed a bit of an issue up front.

The upper is hitting the yoke, must happen when it is getting beat on...

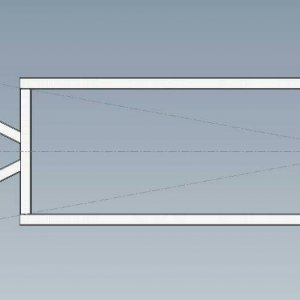

I wondered what the deflection of aluminum links and if they could be allowing it to roll enough to do this? I will post some pictures later for reference.

Heres the deal. I noticed it hit it when I was at MMORV and I broke the front driveshaft. Well, after that I saw there was a cracked weld on the truss where it is welded to the cast. I repaired it and gusseted it to the ram mount. Well, it's polished it clean now and took about a 1/4" sized chunk out of the link.

Has anyone had any issue with aluminum uppers flexing enough to do this? I know the aluminum has a good bit of flex... I will probably sleeve that link with DOM if that is the issue. If it's not I really dont know what else it can be...

The upper is hitting the yoke, must happen when it is getting beat on...

I wondered what the deflection of aluminum links and if they could be allowing it to roll enough to do this? I will post some pictures later for reference.

Heres the deal. I noticed it hit it when I was at MMORV and I broke the front driveshaft. Well, after that I saw there was a cracked weld on the truss where it is welded to the cast. I repaired it and gusseted it to the ram mount. Well, it's polished it clean now and took about a 1/4" sized chunk out of the link.

Has anyone had any issue with aluminum uppers flexing enough to do this? I know the aluminum has a good bit of flex... I will probably sleeve that link with DOM if that is the issue. If it's not I really dont know what else it can be...