-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

End joints and links

- Thread starter Eric

- Start date

crash2

-Oh no I picked a side-

I build my links out of this

http://www3.towerhobbies.com/cgi-bin/wti0001p?&W=001101863&I=LXS021&P=K

And I run these rod ends

http://www3.towerhobbies.com/cgi-bin/wti0001p?&W=001101863&I=LXHGB7&P=K

Its a perfect match as you have to tap both tube/material to 8-32 and then take a chunk of 8-32 all thread and bam--done.

http://www3.towerhobbies.com/cgi-bin/wti0001p?&W=001101863&I=LXS021&P=K

And I run these rod ends

http://www3.towerhobbies.com/cgi-bin/wti0001p?&W=001101863&I=LXHGB7&P=K

Its a perfect match as you have to tap both tube/material to 8-32 and then take a chunk of 8-32 all thread and bam--done.

CHOP SHOP

Well-Known Member

So the aluminum tube gets taped?

A small piece of all thread inserted in to the Aluminum?

THen the ends screw on?

Is that it? or am I missing something?

Where is a good place to get a few taps for this?

the hobby shop also has threaded allen setscrews that are about an inch long.

You can just thread them into the link tube and it will make its own threads, then thread the joint on the end.

No need to cut, drill, tread.

the hobby shop also has threaded allen setscrews that are about an inch long.

You can just thread them into the link tube and it will make its own threads, then thread the joint on the end.

No need to cut, drill, tread.

Hmm that sounds like an easy way to go. A little epoxy and it will be good to go.

crash2

-Oh no I picked a side-

Dril--why when the links I showed the holes are perfect for tapping to 8-32.the hobby shop also has threaded allen setscrews that are about an inch long.

You can just thread them into the link tube and it will make its own threads, then thread the joint on the end.

No need to cut, drill, tread.

Eric just get a tap(any hardware store) because if you don't tap the rod ends you will stretch them out a tad--and they will be prone to weakening. Trust me we put our rigs thru hell at comps and I have seen what holds and what doesn't :awesomework:

CHOP SHOP

Well-Known Member

Dril--why when the links I showed the holes are perfect for tapping to 8-32.

Eric just get a tap(any hardware store) because if you don't tap the rod ends you will stretch them out a tad--and they will be prone to weakening. Trust me we put our rigs thru hell at comps and I have seen what holds and what doesn't :awesomework:

one method is not any stronger or inferior to the other. You just like to more work is all.

one requires less tools and steps.

Actually the setscrews are hardened unlike soft bendy all thread

CHOP SHOP

Well-Known Member

Hmm that sounds like an easy way to go. A little epoxy and it will be good to go.

no epoxy needed. You will have a hard time geting the setscrews out even with an allen. They flat stay put.

Sounds like I will tap the rods, use some lock tight and maybe the set screws instead of all thread.

Actually I will most likely use the all thread, then it should bend before the link and its much easier to replace.

Are the ends all ready threaded? at 8-32?

Now to just find a decent hardware shop with the parts I need.

Actually I will most likely use the all thread, then it should bend before the link and its much easier to replace.

Are the ends all ready threaded? at 8-32?

Now to just find a decent hardware shop with the parts I need.

crash2

-Oh no I picked a side-

one method is not any stronger or inferior to the other. You just like to more work is all.

one requires less tools and steps.

Actually the setscrews are hardened unlike soft bendy all thread

How is the all thread going to bend when the rod end it securly tighted to the link? I have tuned a link into a U-shape at the last comp--all thread was fine.

Do not expoxy anything into the link--just screw them together and be done..

Ends are just a bare bore Eric....

CHOP SHOP

Well-Known Member

Actually I will most likely use the all thread, then it should bend before the link and its much easier to replace.

thats alway nice, something to bend easily.

How is the all thread going to bend when the rod end it securly tighted to the link? I have tuned a link into a U-shape at the last comp--all thread was fine.

Do not expoxy anything into the link--just screw them together and be done..

Ends are just a bare bore Eric....

Sweet, sounds like I need to order a few other things from the hobby shop.

Bending a link is always better then breaking an axle part or something worse.

The only thing left that I am fighting with in my head is it would be nice to keep it all metric threads, less to keep track of. But if its only the links that should be easy to figure out.

thats alway nice, something to bend easily.

Having a known weak link has its advantages, but it sounds like the aluminum still bends first.

crash2

-Oh no I picked a side-

Sweet, sounds like I need to order a few other things from the hobby shop.

Bending a link is always better then breaking an axle part or something worse.

The only thing left that I am fighting with in my head is it would be nice to keep it all metric threads, less to keep track of. But if its only the links that should be easy to figure out.

Thats why I have bully's--they won't break. When my link bent--I was bound up in a hole trying feeverlishly to get out as I had one gate to clear to finish the course. With the setup I have described eric---you won't have anything fail except the pins in the axles till you upgrade them...

The inner dia of the rod ends and tube can also be tapped to 5mm if you wish--its just easier to get standard stuff if you are in a pinch :awesomework:

Thats why I have bully's--they won't break. When my link bent--I was bound up in a hole trying feeverlishly to get out as I had one gate to clear to finish the course. With the setup I have described eric---you won't have anything fail except the pins in the axles till you upgrade them...

The inner dia of the rod ends and tube can also be tapped to 5mm if you wish--its just easier to get standard stuff if you are in a pinch :awesomework:

Thats good to know, so far the axles have taken a few good tumbles and are working well, now I just need to tune it and make it more mine.

If I stick with all metric its less tools and less to keep track of is my thought. I plan on having spares for the weak link when I figure it out, so far I am still trying to break it, its come lose a few times and had a shock come apart but I have yet to find the weak link, waiting for somthing to break:redneck:

The inner dia of the rod ends and tube can also be tapped to 5mm if you wish--its just easier to get standard stuff if you are in a pinch :awesomework:

Are you sure its 5mm and not something smaller. 5mm seams really big from what I can tell, not having one in my hand dosnt help either. And the internet is only so good......

Just want to check before I order some stuff.

Thanks!

crash2

-Oh no I picked a side-

Are you sure its 5mm and not something smaller. 5mm seams really big from what I can tell, not having one in my hand dosnt help either. And the internet is only so good......

Just want to check before I order some stuff.

Thanks!

I can verify tonight Eric....

crash2

-Oh no I picked a side-

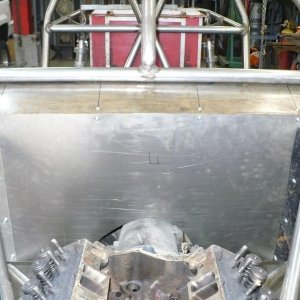

Just got home--heading to the shop shortly :awesomework:

![IMG_3520[1].JPG](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/4/4934-3ac5ace0f796e5d2d56e3da6353f36c7.jpg?1625928495)