I was picking up some new wheel bearings to put my front end back together, and an old timer at the local parts shop got to talking to me.

he said when he was into "Jeepin" (his term) he would install a zerk fitting in the hub so he could fill the assembly with grease, to help keep water out.

Now once I realized this guy wasn't Tranny Frank/Backwoods Goop, I started wondering if anyone has done it and had any success?

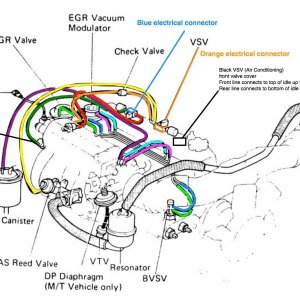

here's where he's telling me to add the fitting, the idea seems like it would work in theory, if its full of grease it can't fill with water.

he said when he was into "Jeepin" (his term) he would install a zerk fitting in the hub so he could fill the assembly with grease, to help keep water out.

Now once I realized this guy wasn't Tranny Frank/Backwoods Goop, I started wondering if anyone has done it and had any success?

here's where he's telling me to add the fitting, the idea seems like it would work in theory, if its full of grease it can't fill with water.