May 2 2007, 07:48 AM

I'm not a big fan of the factory link rod and bell crank BS for the floor shifter linkage. It comes out of adjustment when you twist the rig up off road. I am going to use a hardware store clevis direct linkage like I did on my bronco.

May 3 2007, 03:35 AM

The bracket off the 2.8 that the dip stick bolts to doesn't line up... the 4.0 has a taller deck height than the 2.8/2.9 so it's wider. I zip tied it to the firewall.

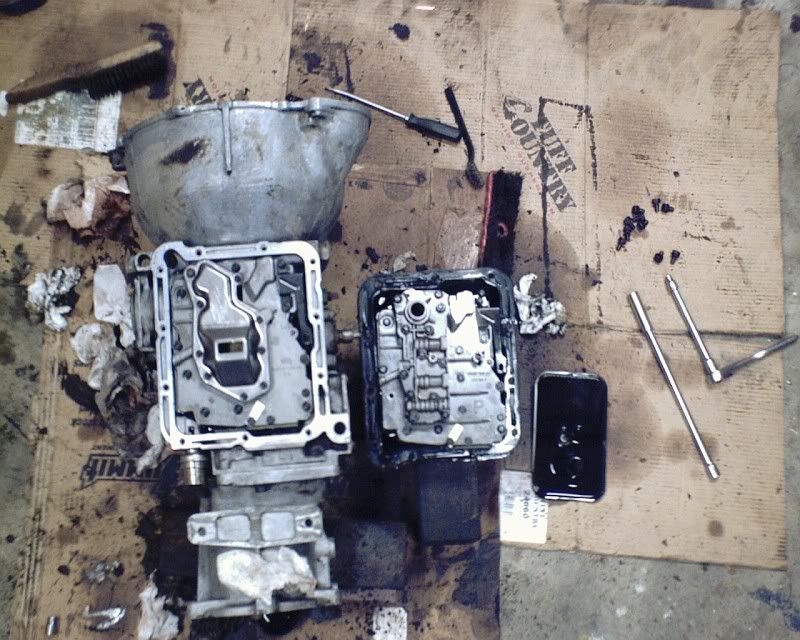

I took the original bracket for the kick down on the trans, flattened the bend in it, and bolted it to the C5 with a low/reverse servo bolt. I also put the kick down arm off the A4LD on the C5. So the kick down is done.

I still have to drop the drive shafts off to get lengthened/shortened, and get to the hardware store to buy the parts for the shift linkage... all that's left after that is to fill the trans/t-case, mount the trans cooler, install new plugs/wires, install the exhaust, and reassemble the interior. Then I can turn the key and see what I got.

May 4 2007, 08:32 PM

May 4 2007, 08:32 PM

Drive shafts got dropped off today. Won't be able to get back on it till Monday.

May 5 2007, 10:29 AM

DENIED...

Every hardware supply store in the area is sold out of 5/16" clevis yokes... and the order time on the yokes is 2 weeks....

So... looks like I get to dig through the 4 corners of the garage to find that bell crank and link rod abortion.

Yesterday, 05:37 PM

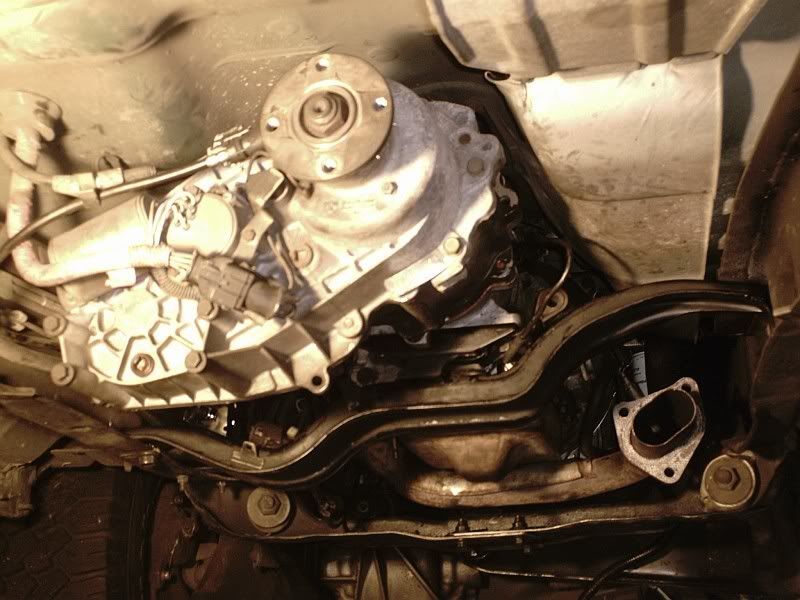

Just got done installing this:

It went in pretty nice.. fits well.

I got the list down pretty good. The trans cooler is mounted and plumbed. Trans lines are plumbed. Grille is back in. Got the new plugs and wires installed. Boy... the passenger side plugs on a 4.0 with A/C are just about as inaccessible as you can get... That side took like and hour and a half for 3 plugs. drool.gif

Gonna start on the interior after dinner... I think i might have an alternative shift linkage figured out....

The factory linkage for the C5 and floor shifter is a no go. The bracket bolt for the block doesn't clear the exhaust down pipe on the driver side... the pivot of the bracket is blocked by the pipe, and the ABS controller is in the spot on the frame that the bell crank pivot would mount...

The drive shaft guy did not call me today.. Hopefully they will be done tomorrow...

It's getting close. :cheer:

Today, 05:16 AM

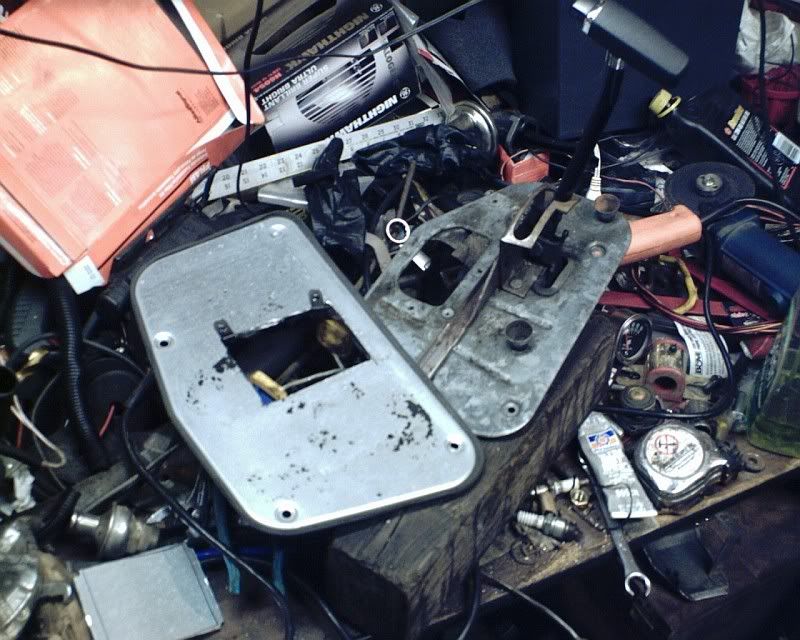

This is what I figured out for the shift linkage. Cost: $0. It's a couple of adjuster pieces from the stock shift linkage, and a piece of 3/8" tube.

I got everything done up to the point of drive shafts and filling the trans and t-case. The NSS wiring works flawless. I have reverse lights, Crank in neutral and park, and the t-case shifts into low range only in neutral and park. I did a happy dance after it shifted all the way into 4lo with just the key in the run position.

The wiring for the NSS goes like this. From the original A4LD harness. Take the red/lt blue striped wire, and splice it to one of the red/lt blue wires on the C5 switch. Take the Pink and red/white striped wires and splice them to the other red/lt blue striped wire on the C5 switch. The other 2 wires you are left with are the black/purple and black/orange wires for the reverse lights. Simply match them with the remaining wires on the C5 switch.

Here's the interior all back together with the floor shifter... I'll be pulling it all back apart to clean it up after I take it for a drive and make sure the trans works properly. I also plan on removing the column shift arm and shift indicator from the instrument cluster.

Here's a crappy pic of the kick down linkage. The arm from the A4LD bolts to the C5. You just have to reroute the cable to point the opposite way from the A4LD and tweak it's mounting bracket to bolt to the lower rear reverse servo cover bolt.

Hopefully my drive shafts will be done today so I can take it for a drive....