85toyo

Well-Known Member

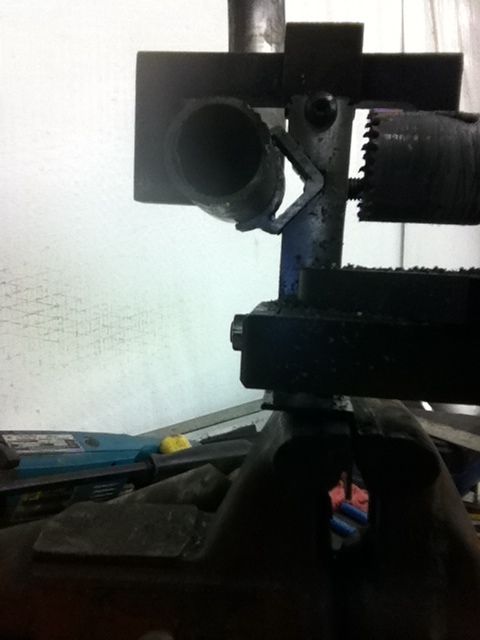

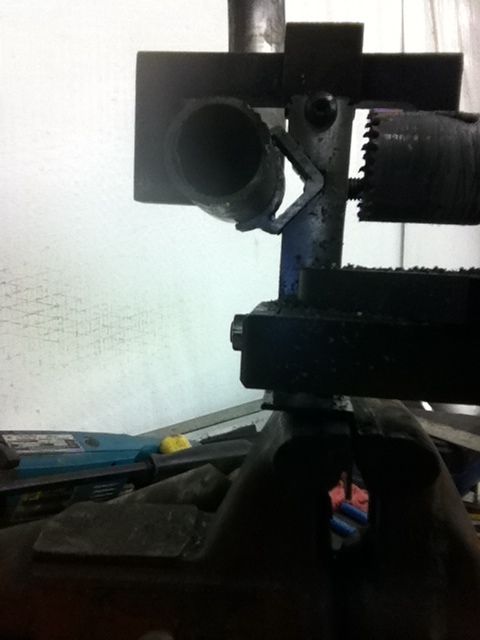

As many of you probably already know this notcher will not notch inside a bend and even worse, close to a bend. I was tired of making these notches with a grinder so I came up with a plan. I picked up a small piece of 2"x1/8" that gave me a 1.75 ID. I cut the tube down the middle and around 2" long so that I had one small piece that could cup the tube i would be notching. Lay the notcher on it's back with the part that holds the tube facing up and measure from the bottom of the v to the face of the steel block. Cut two pieces of plate and form a V for the 2" tube to set in then weld it up. Next the piece of 2" that I cut in half will go on top of that plate and had to be spaced a little because the 3/16 plate wasn't quite thick enough to put it where it needed to be.

This was the end result and I can get better pictures later if someone wants. For reference that is a 90 degree bend setting in the notcher cut off very close to the start of the bend.

This was the end result and I can get better pictures later if someone wants. For reference that is a 90 degree bend setting in the notcher cut off very close to the start of the bend.