So currently in the process of building and Rockwell rig and I have tried to read up on what setups work the best, but there seems to be a little of lack of technical info about each setup and specs that people are acutally using not just what they heard works from some guy on the internet so if you have anything good to add please share.

My setup will be a ls motor with double ended Rams on both axles the rams are 2.5x10 if I recall correctly they are from surplus center and there has been plenty of people use these with very good results I intend to control the front with a orbital and rear with a electric joystick.

First thing i can't decide on is what size orbital to use I am leaning towards a 200cc I think that is around 9.6cu my current rig has a 160cc which is around 7.3cu and running a 2.5x8 psc ram it works good but at high speed you can get behind a little so how fast of a orbital can you go with the pressure that stock pumps produce and still have enough power to turn the tires if I had my way I would love a 1 turn lock to lock orbital but i don't know where that become a big trade off for power also if I do go with a faster orbital is there any options on pump upgrades that would help the pressure to help give it some more power

Pumps this is one were I have done lots of research and tried to learn as much as possible I have talk with a few people from different company's and most of the aftermarket pumps are really just stock pumps that have been rebuild with good OEM quality parts PSC used to offer two different styles of P pumps a 135 and a 185 now they just offer a 135 which is basically a stock pump I have seen people run one P pump for the whole system and run it thur the rear valve first then to the orbital the main downside I see with this is it will only do system at a time so it can be a little hit and miss on when you get steering. I have also considered

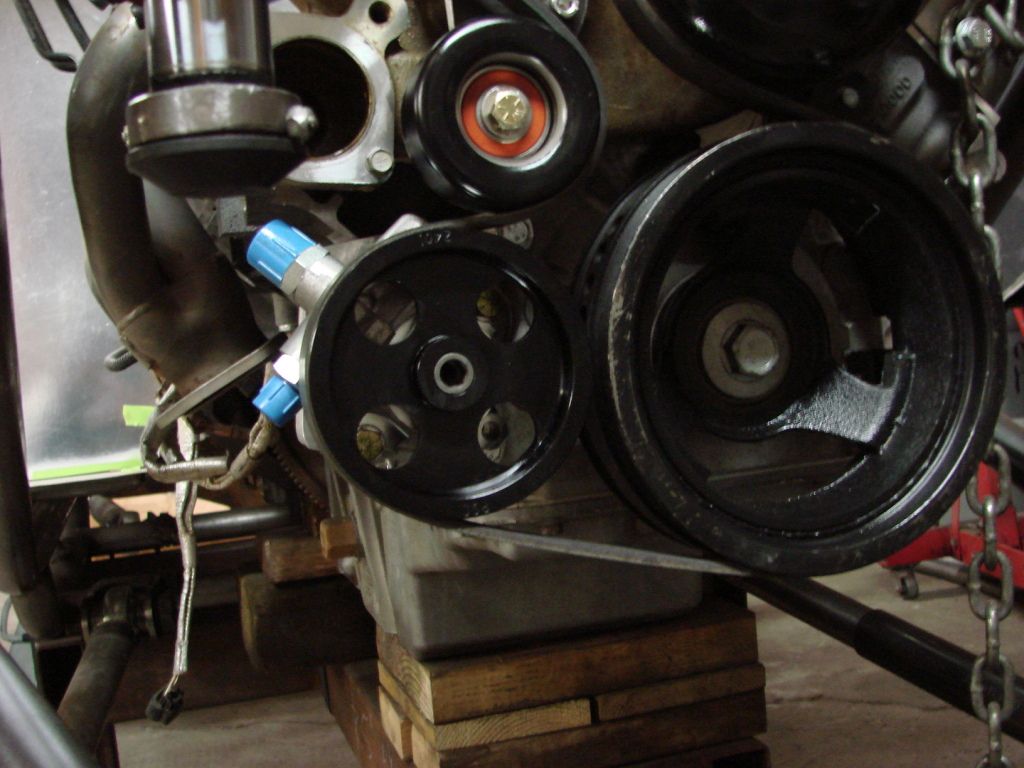

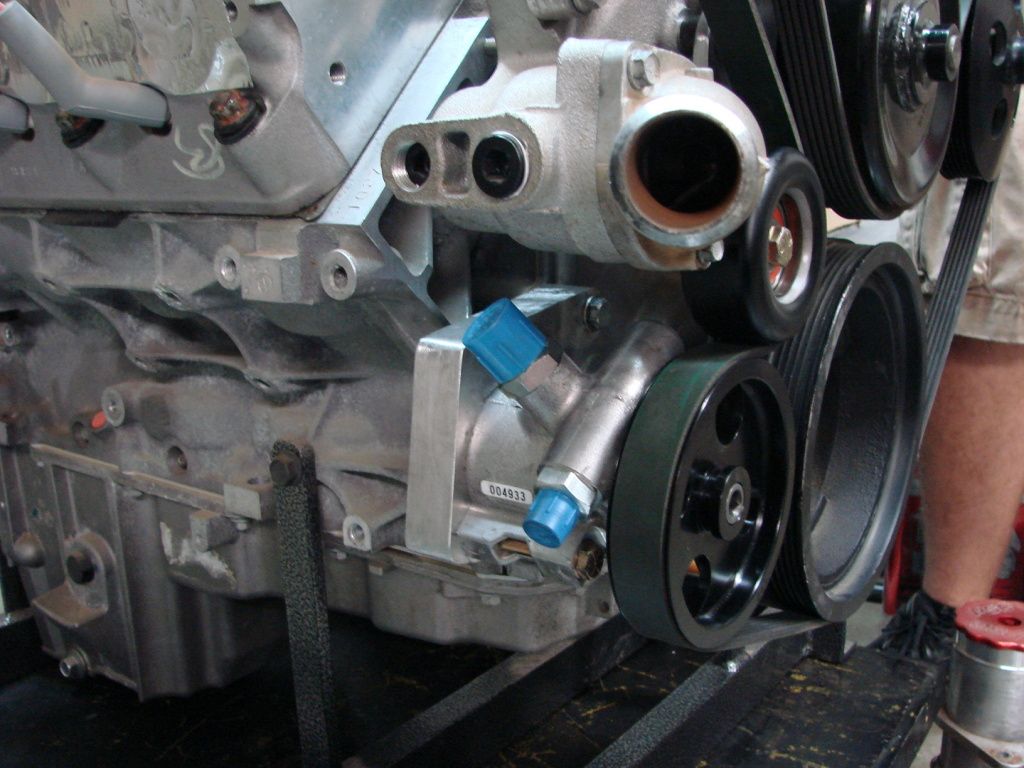

changing pumps and going to a twin pump setup which I am not 100% I could even fit inside the frame rails bc the only brackets I have seen put two pumps on the driverside and the alternator on top passenger so if I could find a bracket that just added a pump on the pass top that would be perfect

The last setup I have heard about but never seen in person is using a 12v hydraulic power unit those can be bought fairly cheap not real sure on speed and issues you might encounter by going that route if someone has info I would love to hear more about it

Well hopefully someone who is a little smarter can shed some light on some of these issues any help is appreciated

My setup will be a ls motor with double ended Rams on both axles the rams are 2.5x10 if I recall correctly they are from surplus center and there has been plenty of people use these with very good results I intend to control the front with a orbital and rear with a electric joystick.

First thing i can't decide on is what size orbital to use I am leaning towards a 200cc I think that is around 9.6cu my current rig has a 160cc which is around 7.3cu and running a 2.5x8 psc ram it works good but at high speed you can get behind a little so how fast of a orbital can you go with the pressure that stock pumps produce and still have enough power to turn the tires if I had my way I would love a 1 turn lock to lock orbital but i don't know where that become a big trade off for power also if I do go with a faster orbital is there any options on pump upgrades that would help the pressure to help give it some more power

Pumps this is one were I have done lots of research and tried to learn as much as possible I have talk with a few people from different company's and most of the aftermarket pumps are really just stock pumps that have been rebuild with good OEM quality parts PSC used to offer two different styles of P pumps a 135 and a 185 now they just offer a 135 which is basically a stock pump I have seen people run one P pump for the whole system and run it thur the rear valve first then to the orbital the main downside I see with this is it will only do system at a time so it can be a little hit and miss on when you get steering. I have also considered

changing pumps and going to a twin pump setup which I am not 100% I could even fit inside the frame rails bc the only brackets I have seen put two pumps on the driverside and the alternator on top passenger so if I could find a bracket that just added a pump on the pass top that would be perfect

The last setup I have heard about but never seen in person is using a 12v hydraulic power unit those can be bought fairly cheap not real sure on speed and issues you might encounter by going that route if someone has info I would love to hear more about it

Well hopefully someone who is a little smarter can shed some light on some of these issues any help is appreciated

My pumps was mounted like wide open designs. Stazworks rearsteer complete system is what I ran and love it Log splitter style works good also just takes up a lot more room than stazworks Plus side with log splitter style is engine doesn't have to be running to be able to steer

My pumps was mounted like wide open designs. Stazworks rearsteer complete system is what I ran and love it Log splitter style works good also just takes up a lot more room than stazworks Plus side with log splitter style is engine doesn't have to be running to be able to steer