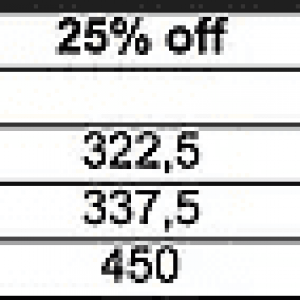

really i am posting this for P... i know he needs beadlocks and loves some keystuns, and hes a cheap mother ****er like me....

anyways, i saw this on pirate so its not my idea, its my take on it, but still not original... i just ordered new ltb's, 40s, and 17" soft 8 wheels, i wanted an internal beadlock but i am to cheap... i was going to run H1s, but i didnt want an adapter in the rear and i also liked the new ltbs, so this is how it works.... at least my take, by using 17" wheels i was able to come up w/ some used low profile 17" tires, most tire shops will give them away... i put the low pro inside of the LTB and and then used a tube in the low pro... you need to put a hole in the low pro as the valve stem for the LTB is inside of it... once it is all mounted, air up the LTB a couple of psi short of the intended pressure, then air up the tube... it is contained by the low pro and just pushes on the inside bead... its just like a staun except i did it for $60, not $700... here is how the tires look prior to mounting, yes they are a bitch to get inside one another, but doable...

this is what they look like mounted, no different than a regular wheel and you can casually brag about how you have internal BL... people will think you are rich, thus allowing you to hang out w/ the likes of MattO.... ;D

mounted...

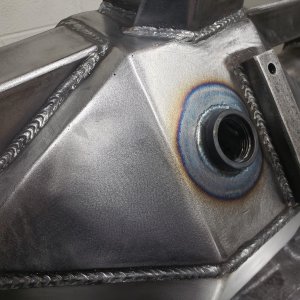

on another note, here is how i weldered up my reinforcement rings... i was going to use the drill directly around the wheel, but it was to fast, so i added the "gear reduction", a 4" hole saw... notice the drill bit in the yellow drill, i used that because it had some grip to turn the belt, then around the hole saw, then another belt from the chuck to the rim... works almost perfect... my best rusults in the pics.... think about this... a 17" rim uses a ring almost 5 ft long w/ two welds per ring and two rings per wheel... thats 80 feet of weld for the set of wheels...

the results... this is two beads around a 3/8" round bar...

here is a video... turn your volume way down... chris was using a grinder just off screen and its LOUD....

anyways, i saw this on pirate so its not my idea, its my take on it, but still not original... i just ordered new ltb's, 40s, and 17" soft 8 wheels, i wanted an internal beadlock but i am to cheap... i was going to run H1s, but i didnt want an adapter in the rear and i also liked the new ltbs, so this is how it works.... at least my take, by using 17" wheels i was able to come up w/ some used low profile 17" tires, most tire shops will give them away... i put the low pro inside of the LTB and and then used a tube in the low pro... you need to put a hole in the low pro as the valve stem for the LTB is inside of it... once it is all mounted, air up the LTB a couple of psi short of the intended pressure, then air up the tube... it is contained by the low pro and just pushes on the inside bead... its just like a staun except i did it for $60, not $700... here is how the tires look prior to mounting, yes they are a bitch to get inside one another, but doable...

this is what they look like mounted, no different than a regular wheel and you can casually brag about how you have internal BL... people will think you are rich, thus allowing you to hang out w/ the likes of MattO.... ;D

mounted...

on another note, here is how i weldered up my reinforcement rings... i was going to use the drill directly around the wheel, but it was to fast, so i added the "gear reduction", a 4" hole saw... notice the drill bit in the yellow drill, i used that because it had some grip to turn the belt, then around the hole saw, then another belt from the chuck to the rim... works almost perfect... my best rusults in the pics.... think about this... a 17" rim uses a ring almost 5 ft long w/ two welds per ring and two rings per wheel... thats 80 feet of weld for the set of wheels...

the results... this is two beads around a 3/8" round bar...

here is a video... turn your volume way down... chris was using a grinder just off screen and its LOUD....