After running Elbe I decided it was time for some sliders, so I went in search and found that the ones I liked were in the ballpark of $380 bucks so I decided to build my own.

This is why I decided to put on sliders

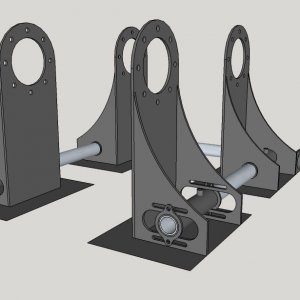

I started with some stamped 1/4" steel that I picked up from the Fab Shop in Edgewood, they usually have a large supply of scraps that you can get fairly inexpensive. It was a little rusty, but a wire brush can clean it up fairly easily

I then got some 1 1/2" Sch 80, they were out of sch 40, the Sch 80 is a 1/4" thick, a little overboard, but it is a slider, I went up to Gibbys and we bent it at 26 degrees on both ends, and cut it so it would fit flush, and welded it up.

We then welded the bottom and sides together.

A little paint makes them look a lot better, I may opt to use a roll on such as line-x, but we'll see how the paint holds up

If you notice in one of the photos above I notched out where it would slide into the body mounts, this was the worst part as I had to cut a 1/4" notch in the rubber mounts, I did this with a grinder, smoky and extremely messy, my arms ended up black with melted rubber, boy was that fun cleaning off, I then lifted the body just enough to take the pressure off the mounts and drove the slider into place.

Prior to installation, I pre-drilled holes for the machine bolts and countersunk them so that they would be flush, after mounting them to the body mounts I drilled the tub and bolted the slider up. Notice I only wash the part of the jeep that I have to.

The bars extend out just a little past my fender flares

Thanks again to Gibby for the use of his bender and welder.

This is why I decided to put on sliders

I started with some stamped 1/4" steel that I picked up from the Fab Shop in Edgewood, they usually have a large supply of scraps that you can get fairly inexpensive. It was a little rusty, but a wire brush can clean it up fairly easily

I then got some 1 1/2" Sch 80, they were out of sch 40, the Sch 80 is a 1/4" thick, a little overboard, but it is a slider, I went up to Gibbys and we bent it at 26 degrees on both ends, and cut it so it would fit flush, and welded it up.

We then welded the bottom and sides together.

A little paint makes them look a lot better, I may opt to use a roll on such as line-x, but we'll see how the paint holds up

If you notice in one of the photos above I notched out where it would slide into the body mounts, this was the worst part as I had to cut a 1/4" notch in the rubber mounts, I did this with a grinder, smoky and extremely messy, my arms ended up black with melted rubber, boy was that fun cleaning off, I then lifted the body just enough to take the pressure off the mounts and drove the slider into place.

Prior to installation, I pre-drilled holes for the machine bolts and countersunk them so that they would be flush, after mounting them to the body mounts I drilled the tub and bolted the slider up. Notice I only wash the part of the jeep that I have to.

The bars extend out just a little past my fender flares

Thanks again to Gibby for the use of his bender and welder.