94xjsport94

I wish I knew more

- Joined

- Feb 21, 2014

- Messages

- 750

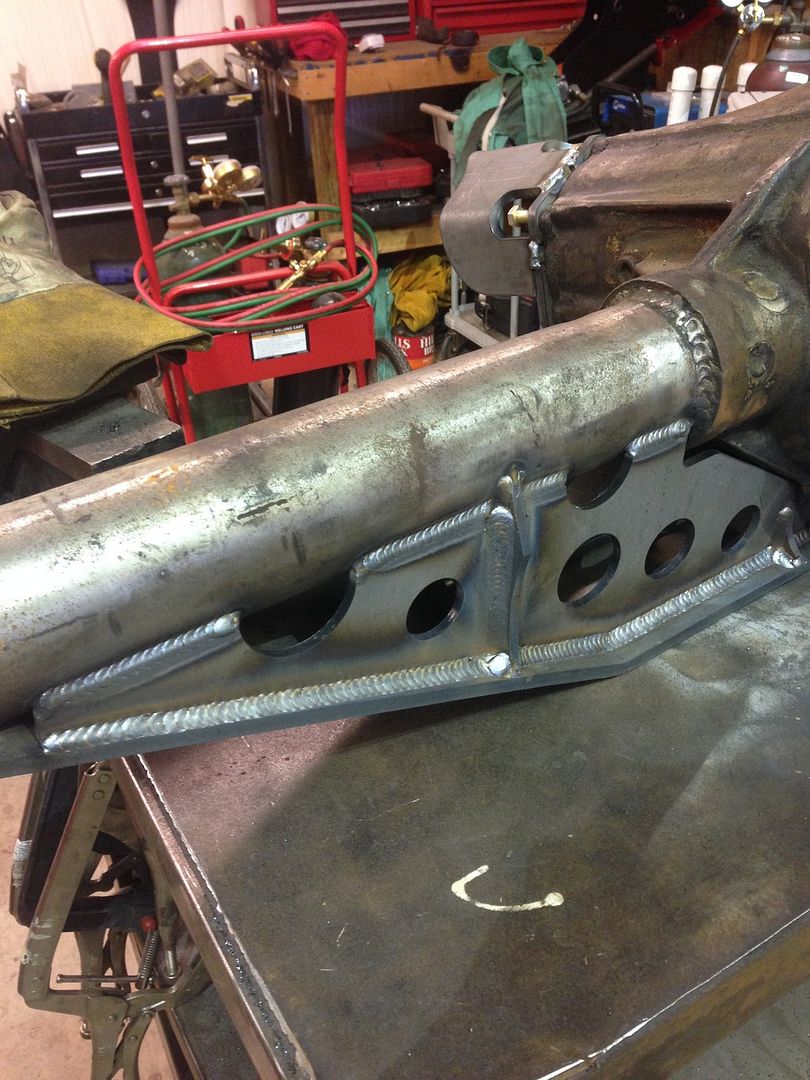

I'm 21 and work in industrial maintenance/ engineer and love to weld and fab stuff up at work and at home. I built a POS XJ on tons and have built and machined some kinda neat stuff at work. I don't have any welding certs yet and I start machining tool classes tomorrow. I have a degree in electronics but pictures of that aren't as cool. I like all types of welding. Burning rods is fun, migging is easier to pick up and throw something together for me though, and I'm learning TIG in my spare time.

This was from tonight. About the second time I have messed with the TIG at work. It's a Miller Dynasty 200 running off 460v, set on DC, lift arc, RMT STD, at 110 amps. 1/4" stainless from the scrap bin I found. I don't know what all the buttons or settings do so forgive my ignorance if they're wrong or I'm being a dumbass with it. Once I finished I realized I didn't really have a defined pattern I was doing with the torch, I was just happy with what resulted. I was going in O's letting the filler Rod get pulled into the puddle instead of "walking the cup" or just dabbing the rod and pushing the puddle.

These were horizontal right to left welds on the flat bar. Sorry, for the shoddy pics, people are finicky about phones at our plant.

Here are some other random welds I've done.

Now, I'd love some tips and advise on any and everything. Post pics of welding, fab, or machinist related stuff!

This was from tonight. About the second time I have messed with the TIG at work. It's a Miller Dynasty 200 running off 460v, set on DC, lift arc, RMT STD, at 110 amps. 1/4" stainless from the scrap bin I found. I don't know what all the buttons or settings do so forgive my ignorance if they're wrong or I'm being a dumbass with it. Once I finished I realized I didn't really have a defined pattern I was doing with the torch, I was just happy with what resulted. I was going in O's letting the filler Rod get pulled into the puddle instead of "walking the cup" or just dabbing the rod and pushing the puddle.

These were horizontal right to left welds on the flat bar. Sorry, for the shoddy pics, people are finicky about phones at our plant.

Here are some other random welds I've done.

Now, I'd love some tips and advise on any and everything. Post pics of welding, fab, or machinist related stuff!