GlipGlop

Well-Known Member

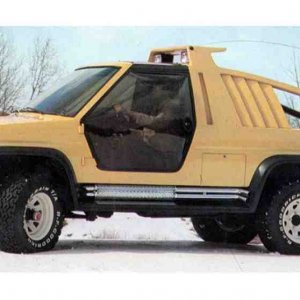

The LJ has been a work in progress since before I ever even had a driver's license. The Jeep is somewhat pulled together currently so I felt that it was a good time to start up a build thread in hopes to share some ideas. I am by no means a professional when it comes to fabrication and so please excuse my work. All I can say is its not the prettiest but I have yet to break a weld.

Anyway, here are the LJ's specs as it currently sits:

2006 Jeep Wrangler Unlimited

4.0L six cylinder

NSG370 straight six backed by a NP231/D300 Doubler clocked for driver side drop and triple stick shifter from JB Custom Fabrications

1310 Carolina Driveline Front CV driveshaft with 1310/13150 bastard joint

1350 Rear CV line also from Carolina

'04 Ford F250 HP60 Superduty front axle

CUCV Full Float 14 Bolt, slightly shaved housing without cutting and welding (inspired by the Roscoe P. Drivetrain tahoe build Verne Simons did for Peterson 4 wheel)

109" wheelbase with double triangulated 4 link rear and 3 link front

2.5" Rancho lift kit springs, 12" Rancho shocks up front, 14" Bilsteins rear

Stock fuel tank moved 4 inches back and pushed up

Mercedes Steering box clocked up

H2 rims wrapped with 38" Falken Wildpeaks

Stock Seats, stock cage, and some other bits and pieces still in holding pattern to further this build along

Blah blah blah, you get the picture. Here's some photos!

![EHCT9062[1].JPG EHCT9062[1].JPG](https://www.hardlinecrawlers.com/attachments/ehct9062-1-jpg.117012/)

![IMG_8452[1].JPG IMG_8452[1].JPG](https://www.hardlinecrawlers.com/attachments/img_8452-1-jpg.117014/)

![IMG_8521[1].PNG IMG_8521[1].PNG](https://www.hardlinecrawlers.com/attachments/img_8521-1-png.117013/)

![IMG_8436[1].JPG IMG_8436[1].JPG](https://www.hardlinecrawlers.com/attachments/img_8436-1-jpg.117015/)

Anyway, here are the LJ's specs as it currently sits:

2006 Jeep Wrangler Unlimited

4.0L six cylinder

NSG370 straight six backed by a NP231/D300 Doubler clocked for driver side drop and triple stick shifter from JB Custom Fabrications

1310 Carolina Driveline Front CV driveshaft with 1310/13150 bastard joint

1350 Rear CV line also from Carolina

'04 Ford F250 HP60 Superduty front axle

CUCV Full Float 14 Bolt, slightly shaved housing without cutting and welding (inspired by the Roscoe P. Drivetrain tahoe build Verne Simons did for Peterson 4 wheel)

109" wheelbase with double triangulated 4 link rear and 3 link front

2.5" Rancho lift kit springs, 12" Rancho shocks up front, 14" Bilsteins rear

Stock fuel tank moved 4 inches back and pushed up

Mercedes Steering box clocked up

H2 rims wrapped with 38" Falken Wildpeaks

Stock Seats, stock cage, and some other bits and pieces still in holding pattern to further this build along

Blah blah blah, you get the picture. Here's some photos!

Last edited: