-

Help Support Hardline Crawlers :

Back to square one.......

- Thread starter Clark

- Start date

Clark

Well-Known Member

Thanks:smokey:

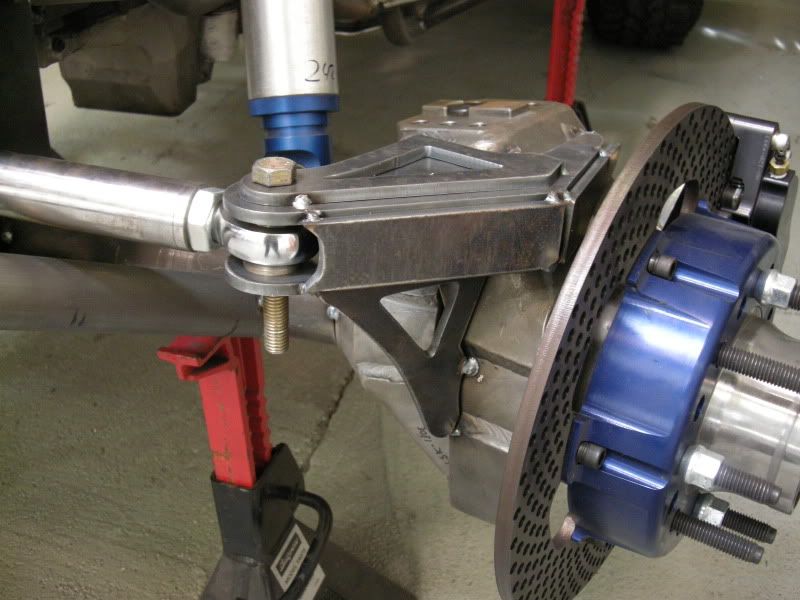

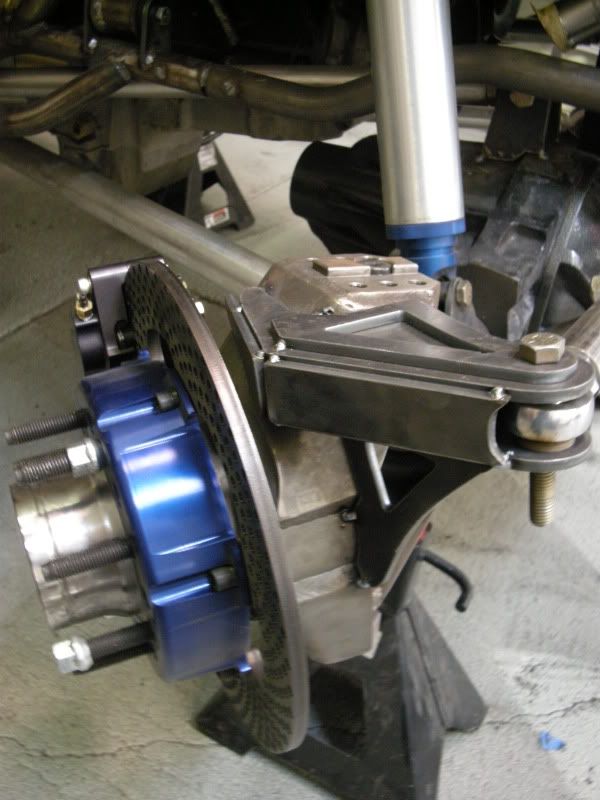

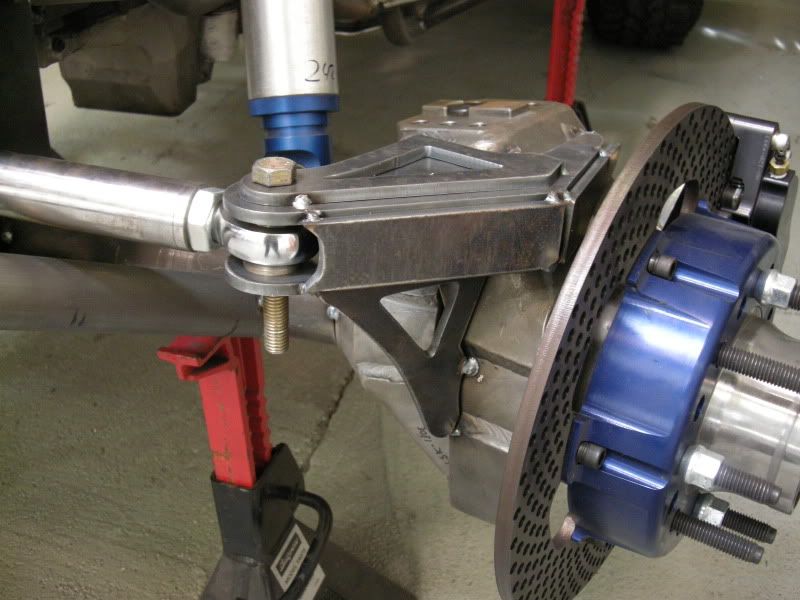

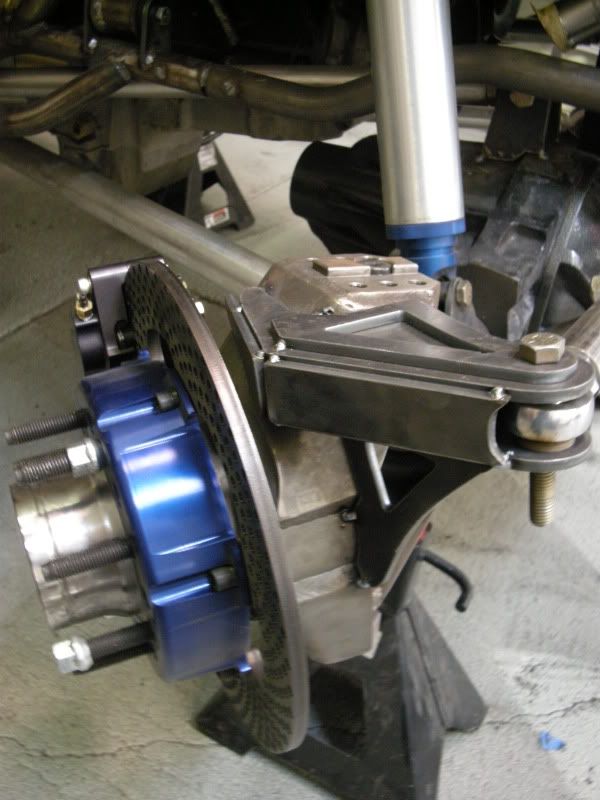

Not a lot, but finished gusseting and plating up the steering arms they're ready to get welded.

Not a lot, but finished gusseting and plating up the steering arms they're ready to get welded.

Money Mark

Well-Known Member

- Joined

- May 19, 2006

- Messages

- 563

- Reaction score

- 0

Make compromises, cut corners......just get it done.:redneck:

Clark

Well-Known Member

I'd be done already if i wasn't always working on someone elses projects.:squirrel:

Money Mark

Well-Known Member

- Joined

- May 19, 2006

- Messages

- 563

- Reaction score

- 0

:kiss:

longfield

Well-Known Member

Nice Clark.:awesomework:

Clark

Well-Known Member

Fixed my upper link mounting issue ontop of the front diff.

zukkev

Cornfuzzled yet again...

Jesus holy mother of axletruss/linkmount/unsprung weight Batman!! Looks cool though!

TreeClimber

Well-Known Member

Be very careful when you weld that sucka, or you'll warp the tubes. I know of another, nearly identical axle that had to be straightened after a virtually identical truss.

Money Mark

Well-Known Member

- Joined

- May 19, 2006

- Messages

- 563

- Reaction score

- 0

You guys gonna suggest how he should use his cutting programs too?:;

Ya....be careful Clark!.....you freaking newb.......you don't even know what you doing, do you?

You guys gonna suggest how he should use his cutting programs too?:;

Shut up retard......If he doesnt want people giving him advice dont post pictures......Nut swinger.

Looks good Clark.:awesomework:

I suggest he ties it in all the way to the c.

As far as programs, Why not get rid of the torchmate software and get something with g codes. Hows that for ya Money dawg?

LOL!!:haha: BrianH just called money a retard!!!!!!

As far as programs, Why not get rid of the torchmate software and get something with g codes. Hows that for ya Money dawg?

LOL!!:haha: BrianH just called money a retard!!!!!!

Last edited:

What are you plans on getting the ring and pinion in with that steering ram mount/gaurd? I suggest doing something like Bunk did on his. That was a pretty slick set up. Im sure you got it figured out though.:awesomework:

Money Mark

Well-Known Member

- Joined

- May 19, 2006

- Messages

- 563

- Reaction score

- 0

:haha:

So there are some butthurt folks out there? My past comments have cut deep, ay?:redneck:

Is this cause you like me......or hate Clark?

So there are some butthurt folks out there? My past comments have cut deep, ay?:redneck:

Is this cause you like me......or hate Clark?

:haha:

So there are some butthurt folks out there? My past comments have cut deep, ay?:redneck:

Is this cause you like me......or hate Clark?

Neither.....:fawkdancesmiley:

Clark

Well-Known Member

Jesus holy mother of axletruss/linkmount/unsprung weight Batman!! Looks cool though!

It's maybe 20lbs extra, i'm still lighter than a stock chevy 60.

I'm going to be very very carefeul.:redneck:Be very careful when you weld that sucka, or you'll warp the tubes. I know of another, nearly identical axle that had to be straightened after a virtually identical truss.

That was great, any sand left in there? or did you get it all out yet? You already asked me about this when you were at my shop, and I showed you there is enough room to get it out as is.:flipoff:Shut up retard......If he doesnt want people giving him advice dont post pictures......Nut swinger.

Looks good Clark.:awesomework:

After the knuckles are welded on i'm going to make new shock mounts that gusset the c to the truss and axle tube and tie it all together, until then i'm leaving it like it is.I suggest he ties it in all the way to the c.

As far as programs, Why not get rid of the torchmate software and get something with g codes. Hows that for ya Money dawg?

LOL!!:haha: BrianH just called money a retard!!!!!!

PS:

G-code is too foreign to me, i'm more at home with MS paint and the like.:haha:

Last edited:

It's maybe 20lbs extra, i'm still lighter than a stock chevy 60.

I'm going to be very very carefeul.:redneck:

That was great, any sand left in there? or did you get it all out yet? You already asked me about this when you were at my shop, and I showed you there is enough room to get it out as is.:flipoff:

After the knuckles are welded on i'm going to make new shock mounts that gusset the c to the truss and axle tube and tie it all together, until then i'm leaving it like it is.

PS:

G-code is too foreign to me, i'm more at home with MS paint and the like.:haha:

:haha::haha::haha:

Money Mark

Well-Known Member

- Joined

- May 19, 2006

- Messages

- 563

- Reaction score

- 0

That stick guy is swinging FAST on those nuts.:haha: