I struggled a little with getting my sheet metal tabs at just the right location and thought maybe this would help others. I'm not sure what other style tabs this works for but I used the ones from poly performance.

I found that a regular sharpie wouldn't go through easily to mark where the hole goes but it will actually thread in well.

So once you have your panel cut and placed where it goes, just use the sharpie tab and run it against the tube until the marker tip bottoms out on the panel.

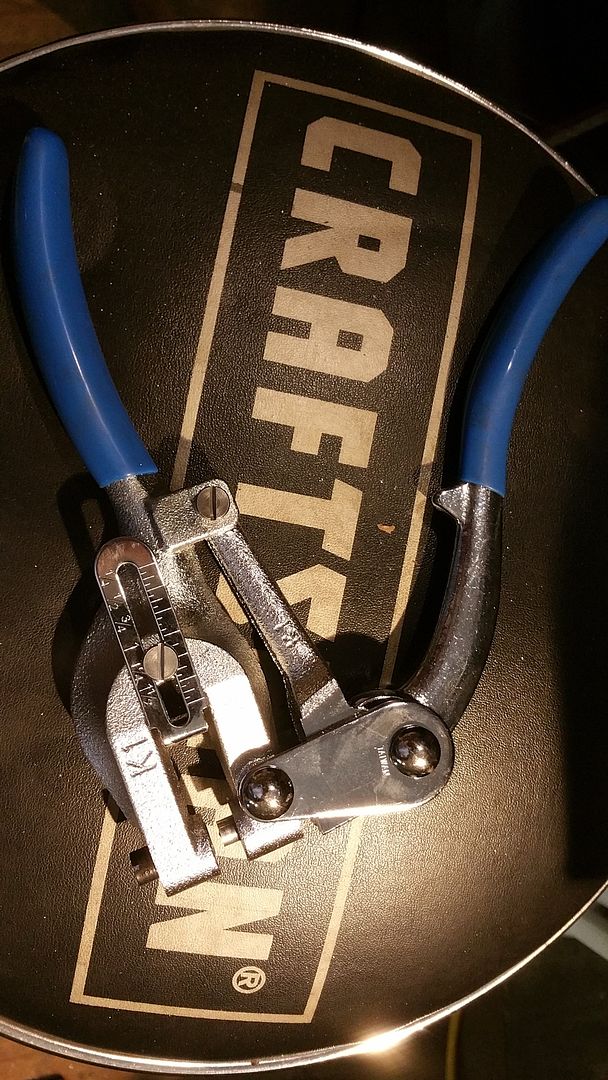

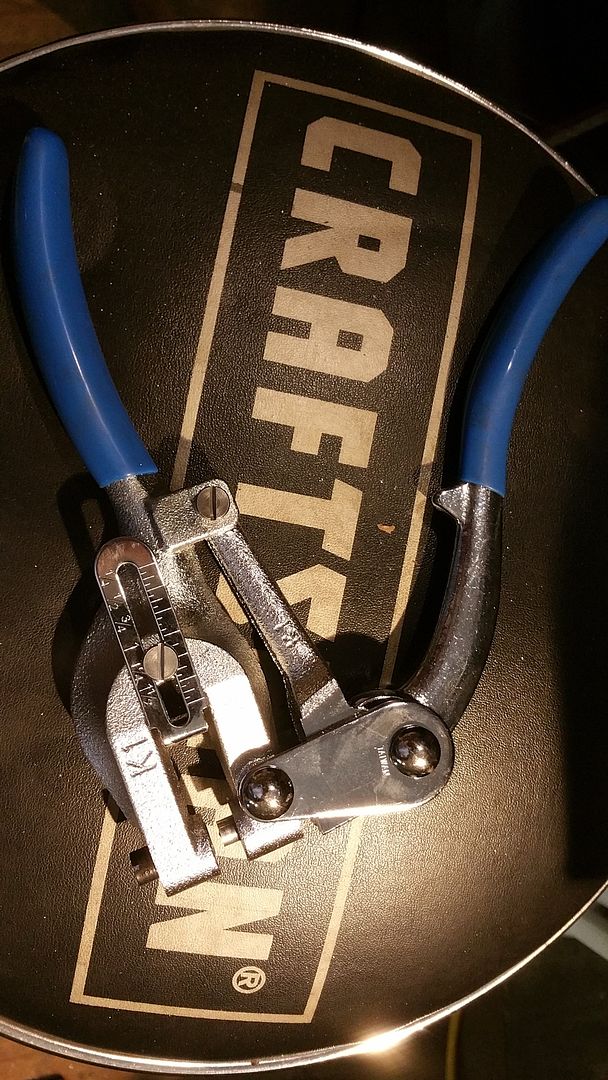

This leaves you with a nice little dot to locate your hole. I use a sheet metal hole punch. It has no problem going through .030 aluminum.

After you get your hole punched/drilled, bolt your tab onto the panel. Then place the panel where it goes and you'll see that you're tab is exactly where it should be, flat against the panel.

Then you're free to go ahead and tack it in.

This is especially helpful when you're working in a tight spot and can only get 1 hand in there. That being said, if your panel doesn't want to sit tight against, you can either stack some heavy wood blocks on it or have someone push from the outside while you mark and tack. Once you get 2 tabs in place to hold your panel securely, you can usually mark, punch and tack all of the rest at the same time.