Totalled

That Ford Guy

I'm shooting for about 5" of lift over stock. I'm using a 4" Tuff Contry lift that will be tweaked. I put the 302 into it last summer. This summer is stronger axles and a winch.

The front axle will be a D35 TTB from a 4.0L Ranger or Explorer replacing the stock D28 TTB. In my case it's from a 1994 Ranger. The rear axle is a 8.8 from a 91 Explorer, replacing the stock 7.5. There's not much really weak about the 7.5 once you lock it or weld it, but the 8.8 has 31 spline shafts vs 28, and 10" vs 9" brakes. Will be geared at 3.73 to start. Tires will be 34x10.50x15 TSL LTBs on stock sploder 15x7 wheels. If I did my figurin' right... with the front and rear axles 1.5" wider than the stock BII, and the 4" BS vs the stock 3.75" wheels, I whoud have the tires right at the edge of the wheel well lips... hopefully I won't have to do anything but add mudflaps...

Anyway, here's what I have done so far:

3-18-06

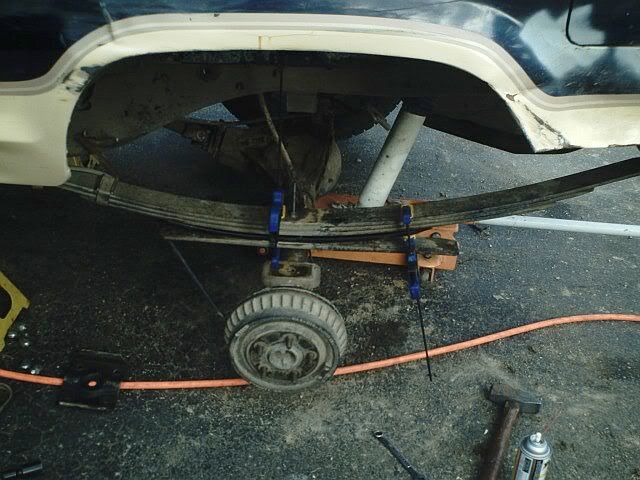

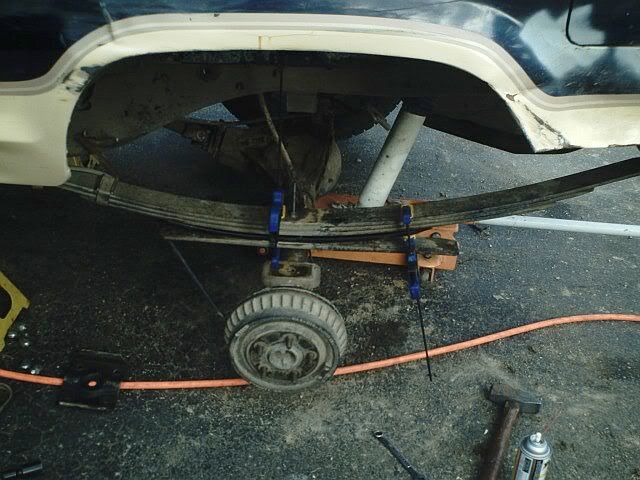

The shackles are the chevy drop units from summit. The are 7.5" long. Stock are 4.5" long. The shackles gave me 1.75" of lift. The add a leafs gave me another 2" of lift. So, with the 1.5" the exploder springs already gave me, I'm now 5.25" over stock in the back. Front next...

4-2-06

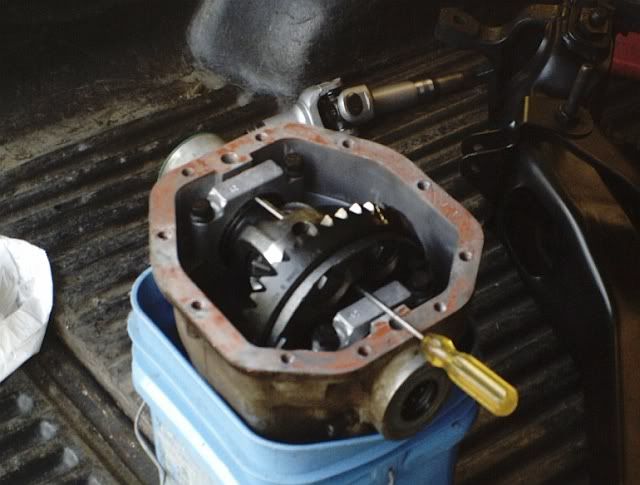

Tore the D35 apart today. fawkin A. This thing was rode hard and put away wet and broke. The driver's side spindle had the inner bearing spin and then weld itself to the spindle, and was driven on till the bearing cage desintegrated, and the rollers fell out when I pulled the rotor off... both sides had more mud than grease in the bearings, and both beams had mud/sand/ect packed in them from the joints to the pig. I got to replace every seal in this thing except the pinion seal, all the wheel bearings, the joints, and probably the rotors. Earlier I debated just lifing the truck and running the D28 and 7.5.... we'll see how long it takes to piece this back together...

Spindle:

4-3-06

Replacing every seal and bearing in a D35 but the pinion and carrier: $158

Not having to tear it apart any time soon: Priceless.

The front axle will be a D35 TTB from a 4.0L Ranger or Explorer replacing the stock D28 TTB. In my case it's from a 1994 Ranger. The rear axle is a 8.8 from a 91 Explorer, replacing the stock 7.5. There's not much really weak about the 7.5 once you lock it or weld it, but the 8.8 has 31 spline shafts vs 28, and 10" vs 9" brakes. Will be geared at 3.73 to start. Tires will be 34x10.50x15 TSL LTBs on stock sploder 15x7 wheels. If I did my figurin' right... with the front and rear axles 1.5" wider than the stock BII, and the 4" BS vs the stock 3.75" wheels, I whoud have the tires right at the edge of the wheel well lips... hopefully I won't have to do anything but add mudflaps...

Anyway, here's what I have done so far:

3-18-06

The shackles are the chevy drop units from summit. The are 7.5" long. Stock are 4.5" long. The shackles gave me 1.75" of lift. The add a leafs gave me another 2" of lift. So, with the 1.5" the exploder springs already gave me, I'm now 5.25" over stock in the back. Front next...

4-2-06

Tore the D35 apart today. fawkin A. This thing was rode hard and put away wet and broke. The driver's side spindle had the inner bearing spin and then weld itself to the spindle, and was driven on till the bearing cage desintegrated, and the rollers fell out when I pulled the rotor off... both sides had more mud than grease in the bearings, and both beams had mud/sand/ect packed in them from the joints to the pig. I got to replace every seal in this thing except the pinion seal, all the wheel bearings, the joints, and probably the rotors. Earlier I debated just lifing the truck and running the D28 and 7.5.... we'll see how long it takes to piece this back together...

Spindle:

4-3-06

Replacing every seal and bearing in a D35 but the pinion and carrier: $158

Not having to tear it apart any time soon: Priceless.

Last edited:

![IMG_3265[1].JPG](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/4/4803-a828f8f733a952743efd4d457d3cf473.jpg?1625928482)