It's been a while since I've updated this thread...not that I've done a

whole lot since the last update...

Since my last update, I still haven't ordered a new rear driveshaft, nor have I finished the cage...but, I have gotten some work in on it here and there.

Shortly after my last post, I tried to get measurements for the rear driveshaft. The best I could do was lift the rear end with an engine hoist. I didn't trust the measurements...but the exercise was entertaining

This shot was after lowering the hoist a bit to get the rear-driver side tire back onto the ground. The front was still firmly planted, but the rear is too light to allow full flex (there was still shaft showing on the rear shocks) :haha:

Through ^^ that ^^ process, I found that I have a bit of front fender trimming to do. Bugger -- I rather like the body lines on the front of this vintage Toyota.

When I'd turned the Cow around in the garage last (before measuring for the driveshaft), I hit just the wrong angle in the driveway. I found the shortcoming with the RCI 2161a -- The fuel pickup tube. Yeah, with a gallon or so of gas in the cell, there wasn't enough in there for the pickup tube to grab. The Cow was floundering in my own driveway... Not cool.

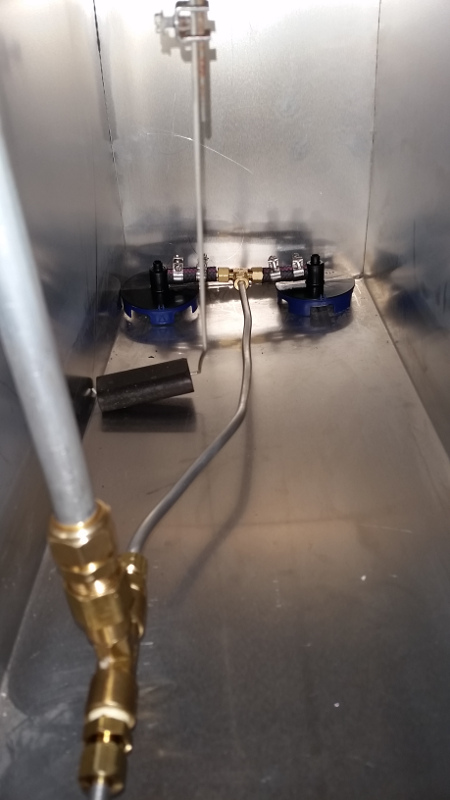

...so, I threw some Walbro's in there...

They seem to be working, but I haven't had it out of the garage yet to see if they actually fix the problem.

Another thing that's annoyed me for years is having to climb into the bed with a funnel to pour gas in the cell. I really don't like wasting stuff, and completely replacing the filler "neck" that came with the RCI seemed like a waste. So, I ordered up some 1.75" fuel filler hose, and proceeded to try to massage the original filler cap/neck to fit. That was wasted effort. I then set out to hunt down an after market 1.75" filler neck setup... More wasted effort. After hacking up the original RCI filler neck in a futile attempt to create my own filler neck, I stumbled across a post that mentioned that the Jaz 45* neck had a "flapper" to prevent it from spilling fuel up the filler neck in the case of a rollover... That finally sold me on getting another neck...so, I did. I grabbed a remote filler setup to go with it.

Installed:

(that shot is from before running over to Home Depot to grab enough matching nuts and bolts to fully mount the filler neck)

Now, I'm off for a couple of weeks (burning vacation time). The wife and kids are all working, and I couldn't go on the long distance (motorcycle) road trip that I'd planned, so I'm screwing around with the Cow again

The biggest problem I've had with the cage is head room (surprise!). I've already revamped the B pillar a bit to give me some more room, and that certainly helped...but after adding some braces up top, I could hit my head on them by simply sitting upright.

I sat on it for a long time, trying to think of schnazzy ways to address the headroom, but I really couldn't come up with anything that seemed to really fix the problem

and was strong. I actually contemplated just lopping off the lid (again) so I could build a cage that was actually safe.

Then, it dawned on me -- turn the braces around a bit...

Doing this moved the braces enough that they're not directly over the head of either seat, and gained about 4.5" of clearance between the noggin and the brace.

I think I'm finally happy (enough) with the cage and seat mounts to start the final welding.

With the heat that's expected over the next few days, I probably won't be spending much time out in the garage...especially not doing any welding. I'm expecting to pick back up on Monday. In the meantime, I may throw the driver's seat back in and see if I can get some better driveshaft measurements by climbing the retaining wall in the front yard :redneck: