HotwheelsYJ

Well-Known Member

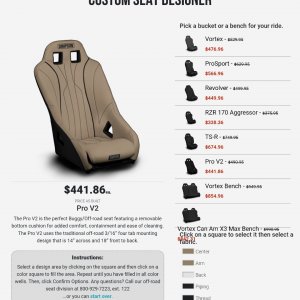

Chuck up on the original tailshaft extension housing. cut it down to 2.5" then bore for the seal 2.750 x 0.505 deep (national seal 3946 - same a stock)zeke392 said:I read about a couple hack & taps before but not much detail. Being a machinist I am sure I can do all required machine work, can we get a list of parts?

Start with a Neapco N3-23-9163X slip flange yoke. I didnt realize till now that a 32 spline slip is cut different than a 32 spline fixed shaft.

Here's my rough print of what to cut the slip to. The counter bores in the bottom are to clear the snap ring on the output shaft. Your flange yoke bolt pattern & pilot may be different. I just modified it to work with what I already had laying around.

Last, slide everything together, mark the output shaft just shorter than the end of the yoke. cut it off & drill & tap for 1/2-20 bolt. Use a heavy washer to hold it together & blue loctite for insurance.