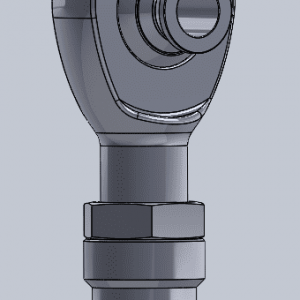

So might be some truth to what he said. The pic shows where the column wants to sit when not restrained. Steers fine like that. Also acts up a little when I bolt it back up, but not as bad as before. I also noticed that not only did the column go down, but it also moved out, like towards the seat. So it seems possible that the combination of being forced up and in was acting on the valve. That said, I have no idea how it got that far off since I had it together and apart a couple of times between building and painting it. Maybe since the orbital mount was the last thing I welded up, it might've warped a little which equals a lot by the time you get to the end of the column. Didn't seem like I forced it into position on final assembly. Either way, looks like it might be my fault and if all I have to do is remake the column mount, I'll take it. At least I found it before I made a nice dash that fit around the column.

View attachment 124453