Dan_Goodwin

Birmingham, AL

- Joined

- Sep 5, 2012

- Messages

- 129

- Reaction score

- 72

Wiring Part 1 – The Approach

The wiring for this swap seems to be what scares people the most. The intention of this post is to provide a guide for how to pick up the FSM from both your donor and your TJ and work through this swap.

My search for a donor started with confirming which vehicles would be compatible with the TJ's CCD Bus setup. Break out the Google machine if you're unfamiliar with that as there is a ton of information online that I won't get into here. I wasn't terribly picky on what my donor rig was, so I bought what I could get cheap and around here that's Durangos. I also have a but of a soft spot for the GCs and would hate to cut one up. So far I haven't found anything that makes a Durango (and I'll loop Rams and Dakotas in here too) substantially better or worse than a Grand Cherokee. I'll touch on those differences later once I've confirmed what works from the Dodge.

Remember, I am going from a 1997 2.5L AX-5 to a 1999 5.9L 46RE out of a Durango. Everything engine related would apply if I kept a manual transmission, but since I am swapping an automatic transmission in place of a manual, I elected to use the Dodge engine harness and make it 'plug in' to the Jeep harness. There are too many circuits related to the automatic transmission I'd need to add to the TJ harness for it to make sense as the base.

Both the Dodge and Jeep have 3 plugs on the PCM; 1 is a body harness and the other 2 are engine related. Additionally, there are 2 plugs that tie into the PDC to provide power and grounds (C103 and C104 on the TJ and C105 and C106 on the Dodge). This means that you can separate the 'engine' harness from the rest of the wiring harness. The PDC plugs for both the Dodge(C105/C106) and the TJ (C103/C104) have many of the same circuits in them but utilize different plugs which prevents this from being a re-pin, plug and play deal.

Now, let's talk about the splicing / de-pinning that many other threads mention. Splices are fine when done correctly, but that's a pretty tedious process. Add to that the factory connectors are over 20 years old and very brittle, so de-pinning them would likely end up with a broken connector. And I'd probably end up with the pin tool stuck through my hand.

To avoid all of that, my goal is to cut the plugs off the factory harnesses and swap to a common Deutch/Molex/ Delphi type plug where I can match the pins to their prospective circuits, plug it in and go. As mentioned before, I didn't want my TJ down for a long time during the swap, so I purchased a 97 TJ 2.5/AX-5 engine bay harness, including the PDC, off eBay for about $150. I bought. It occurred to me later that since I'm swapping to an automatic, it might have made more sense to purchase an automatic TJ harness since the control relay would already be there. Even if you don't buy a spare harness, I'd strongly recommend unplugging your TJ harness and laying it out on a table.

It took me a minute to figure out where to get information in the FSM. THIS thread and THIS thread were beneficial to read through. Here's what I learned:

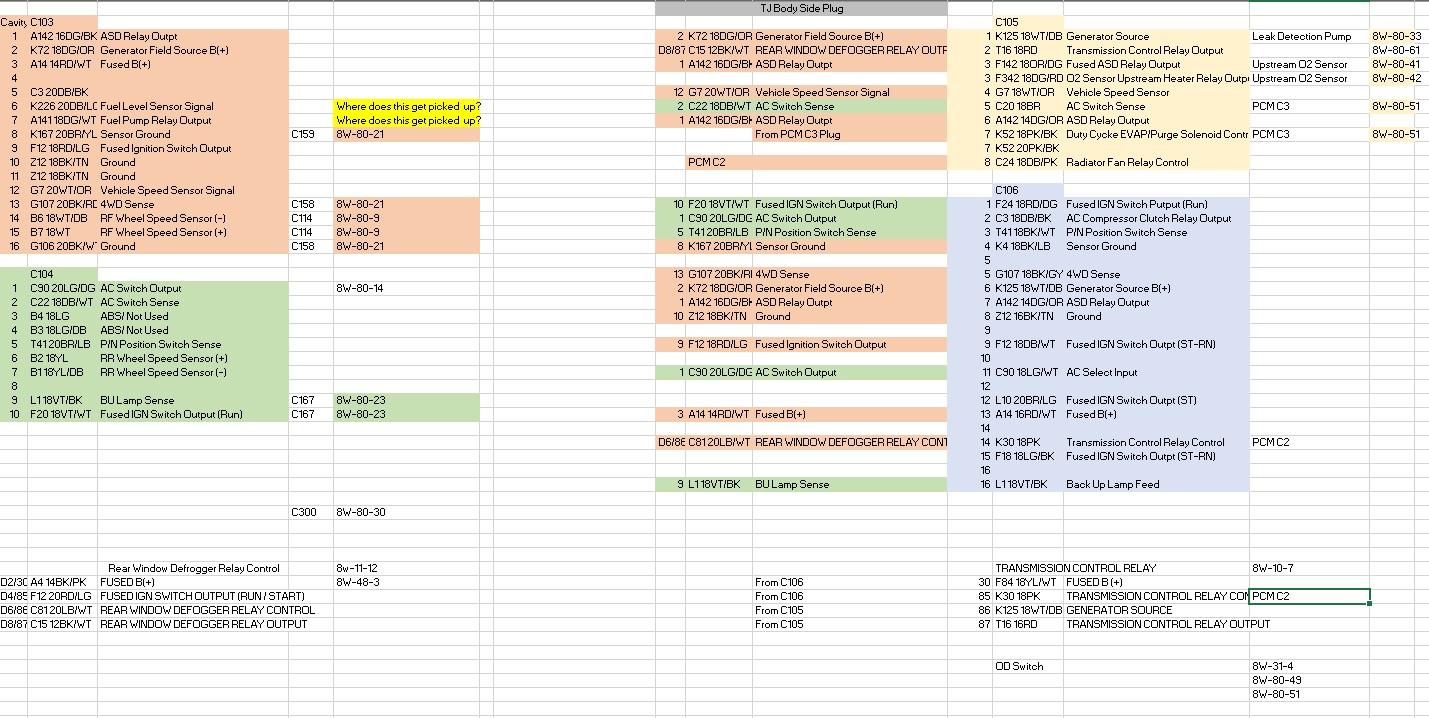

• Since all the changes were being made at the C103/C104 and C105/106 plugs, and many of these are fed from the PCM, I started looking at the PCM circuit descriptions under the Connector Pin Out section. I built a simple Excel spreadsheet that listed the cavity number, circuit number, wire color and size, and page number. This Excel sheet has been major asset for the electrical portion of this project. A link to it can be found HERE.

• Review the rest of the Connector Pin Out Section and fill in the remainder of the circuits. Be sure to note what plug it appears on and page number in case its needed for future reference.

• Compare the TJ C103/C104 to the Dodge C105/106 and make notes of what matches. I used the spreadsheet to create pinout guide by copying and pasting. The neat thing about this swap is that many circuits use the same (or similar) wire colors, gauges and descriptions.

Here is a sample of the spreadsheet I created:

Part 2 will get into the actual execution of this plan.

The wiring for this swap seems to be what scares people the most. The intention of this post is to provide a guide for how to pick up the FSM from both your donor and your TJ and work through this swap.

My search for a donor started with confirming which vehicles would be compatible with the TJ's CCD Bus setup. Break out the Google machine if you're unfamiliar with that as there is a ton of information online that I won't get into here. I wasn't terribly picky on what my donor rig was, so I bought what I could get cheap and around here that's Durangos. I also have a but of a soft spot for the GCs and would hate to cut one up. So far I haven't found anything that makes a Durango (and I'll loop Rams and Dakotas in here too) substantially better or worse than a Grand Cherokee. I'll touch on those differences later once I've confirmed what works from the Dodge.

Remember, I am going from a 1997 2.5L AX-5 to a 1999 5.9L 46RE out of a Durango. Everything engine related would apply if I kept a manual transmission, but since I am swapping an automatic transmission in place of a manual, I elected to use the Dodge engine harness and make it 'plug in' to the Jeep harness. There are too many circuits related to the automatic transmission I'd need to add to the TJ harness for it to make sense as the base.

Both the Dodge and Jeep have 3 plugs on the PCM; 1 is a body harness and the other 2 are engine related. Additionally, there are 2 plugs that tie into the PDC to provide power and grounds (C103 and C104 on the TJ and C105 and C106 on the Dodge). This means that you can separate the 'engine' harness from the rest of the wiring harness. The PDC plugs for both the Dodge(C105/C106) and the TJ (C103/C104) have many of the same circuits in them but utilize different plugs which prevents this from being a re-pin, plug and play deal.

Now, let's talk about the splicing / de-pinning that many other threads mention. Splices are fine when done correctly, but that's a pretty tedious process. Add to that the factory connectors are over 20 years old and very brittle, so de-pinning them would likely end up with a broken connector. And I'd probably end up with the pin tool stuck through my hand.

To avoid all of that, my goal is to cut the plugs off the factory harnesses and swap to a common Deutch/Molex/ Delphi type plug where I can match the pins to their prospective circuits, plug it in and go. As mentioned before, I didn't want my TJ down for a long time during the swap, so I purchased a 97 TJ 2.5/AX-5 engine bay harness, including the PDC, off eBay for about $150. I bought. It occurred to me later that since I'm swapping to an automatic, it might have made more sense to purchase an automatic TJ harness since the control relay would already be there. Even if you don't buy a spare harness, I'd strongly recommend unplugging your TJ harness and laying it out on a table.

It took me a minute to figure out where to get information in the FSM. THIS thread and THIS thread were beneficial to read through. Here's what I learned:

• Since all the changes were being made at the C103/C104 and C105/106 plugs, and many of these are fed from the PCM, I started looking at the PCM circuit descriptions under the Connector Pin Out section. I built a simple Excel spreadsheet that listed the cavity number, circuit number, wire color and size, and page number. This Excel sheet has been major asset for the electrical portion of this project. A link to it can be found HERE.

• Review the rest of the Connector Pin Out Section and fill in the remainder of the circuits. Be sure to note what plug it appears on and page number in case its needed for future reference.

• Compare the TJ C103/C104 to the Dodge C105/106 and make notes of what matches. I used the spreadsheet to create pinout guide by copying and pasting. The neat thing about this swap is that many circuits use the same (or similar) wire colors, gauges and descriptions.

Here is a sample of the spreadsheet I created:

Part 2 will get into the actual execution of this plan.