Next thing I worked on was the power steering pump.

My YJ has a PSC pump (Saginaw style, AMC canister). This has been ran for many years, and the pump finally died. So I bought a new PSC pump, and sent the old one back to have them re-man it. That pump has been sitting in my tool bag for the last several years. Since I'm pretty sure the stock GM pump on the TJ won't have enough 'oomph' to turn the 42s, I thought today would be a good day to swap out the GM pump for the PSC pump.

Wish I'd taken pics, but you know what a GM power steering pump looks like. Anyhow, I did have to switch out the AMC canister for the GM canister, and switch the AMC bracket for the GM bracket, and the AMC pulley for the GM pulley, but that's all pretty easy stuff.

Got the new pump on and installed, but didn't have any more fluid. So it's off to the store tomorrow.

Also, I've ordered some bulkhead flanges and air cleaner adapters to assist with the snorkel conversion, but those parts haven't arrived yet.

I did get my fancy-shmancy fire extinguisher brackets for the roll bar, but I don't want to install those until after the roll bar remodel and re-paint.

Anyhow, I'm still workin. I'm just glad I'm kinda clean, after all the wheelbearing grease, 90 wt axle fluid that leaked out, and power steering fluid mess from today.

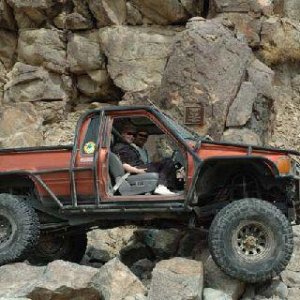

![fourwheelin' 020[1].JPG](http://attachments.www.hardlinecrawlers.com/xfmg/thumbnail/28/28291-3a4742b42c40b6fe445c885b7afb2f66.jpg?1652267392)