-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Low Budget rear engine, 37"s

- Thread starter RustyC

- Start date

pennsylvaniaboy

Well-Known Member

what did you do for side gears in the 3rds and what did you use for front seals in the tubes?

pennsylvaniaboy

Well-Known Member

RustyC said:35 spline spools front and rear. Seals-it axle seals in the front housing.

So did you already have big bearing 3rds? Or can you use any 9"

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

- Reaction score

- 86

There are 35 spline spools available for a stock small bearing third member. They are thin in the spline area and may crack and fail if pushed hard enough. I used that style spool in stock third members until the third cracked. Luckily found it before it spit the pinion out on the ground. I am still using the same spools in big bearing nodular thirds with thicker bearing races for the time being. They are holding up fine with low horsepower.

I suggest getting nodular thirds from Strange, Yukon etc it is a little $ up front but will save the headache later. The stock third WILL crack or completely fail around the pinion.

I suggest getting nodular thirds from Strange, Yukon etc it is a little $ up front but will save the headache later. The stock third WILL crack or completely fail around the pinion.

drycreekjeep

Well-Known Member

Are you gonna race this buggy any this year?

pennsylvaniaboy

Well-Known Member

RustyC said:There are 35 spline spools available for a stock small bearing third member. They are thin in the spline area and may crack and fail if pushed hard enough. I used that style spool in stock third members until the third cracked. Luckily found it before it spit the pinion out on the ground. I am still using the same spools in big bearing nodular thirds with thicker bearing races for the time being. They are holding up fine with low horsepower.

I suggest getting nodular thirds from Strange, Yukon etc it is a little $ up front but will save the headache later. The stock third WILL crack or completely fail around the pinion.

awesome info! Did you just flip the stock 3rds? did that cause the failure at all?

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

- Reaction score

- 86

The entire axle housings were flipped. Stock thirds fail / crack when run in the original setup and flipped the castings are just weak. The third member didn't crack at the spool. It cracked around the pinion. Not related to running the spool.

tonedog702

Well-Known Member

I really like your rig! Do you think the drivetrain would have been okay if you did not race it? Did you do anything special to oil the bearings in the third members?

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

- Reaction score

- 86

Thanks for the complement. I think the original engine failed because I was a used engine and I didn't know any history on it. The 4.3 in it now has a standard 2wd oil pan and pickup and has no oil pressure issues climbing..just not enough hp.

No special oil in the axles, they are just over filled so the pinion bearing get bathed in oil and not overheat.

One of the cheap rock auto unit bearing did finally fail on my last trip to Hawk Pride. I think having water in the front tires and bumping ledges was too much for it.

TBITOY probably nailed it being a thin spindle due to the bushing. I will try to get it out of the trailer and check it out asap and will report what is found

No special oil in the axles, they are just over filled so the pinion bearing get bathed in oil and not overheat.

One of the cheap rock auto unit bearing did finally fail on my last trip to Hawk Pride. I think having water in the front tires and bumping ledges was too much for it.

TBITOY probably nailed it being a thin spindle due to the bushing. I will try to get it out of the trailer and check it out asap and will report what is found

drycreekjeep

Well-Known Member

post some new pictures of it please. I would really like to build a buggy like this one!!!!!

grcthird

Birmingham, AL

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

- Reaction score

- 86

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

- Reaction score

- 86

Test fitting was sketchy using a high lift to check clearances.. I swapped the truck oil pan for a pan from a Trailblazer SS. It is a factory front sump pan that will keep the pickup submerged with the nose uphill being rear engine. Lucky for me the new pan has a built in burrito / hot pocket cooker.

If you are not mocking up exhaust pool noodle yall are missing out.

If you are not mocking up exhaust pool noodle yall are missing out.

RustyC

Well-Known Member

- Joined

- Dec 15, 2010

- Messages

- 1,251

- Reaction score

- 86

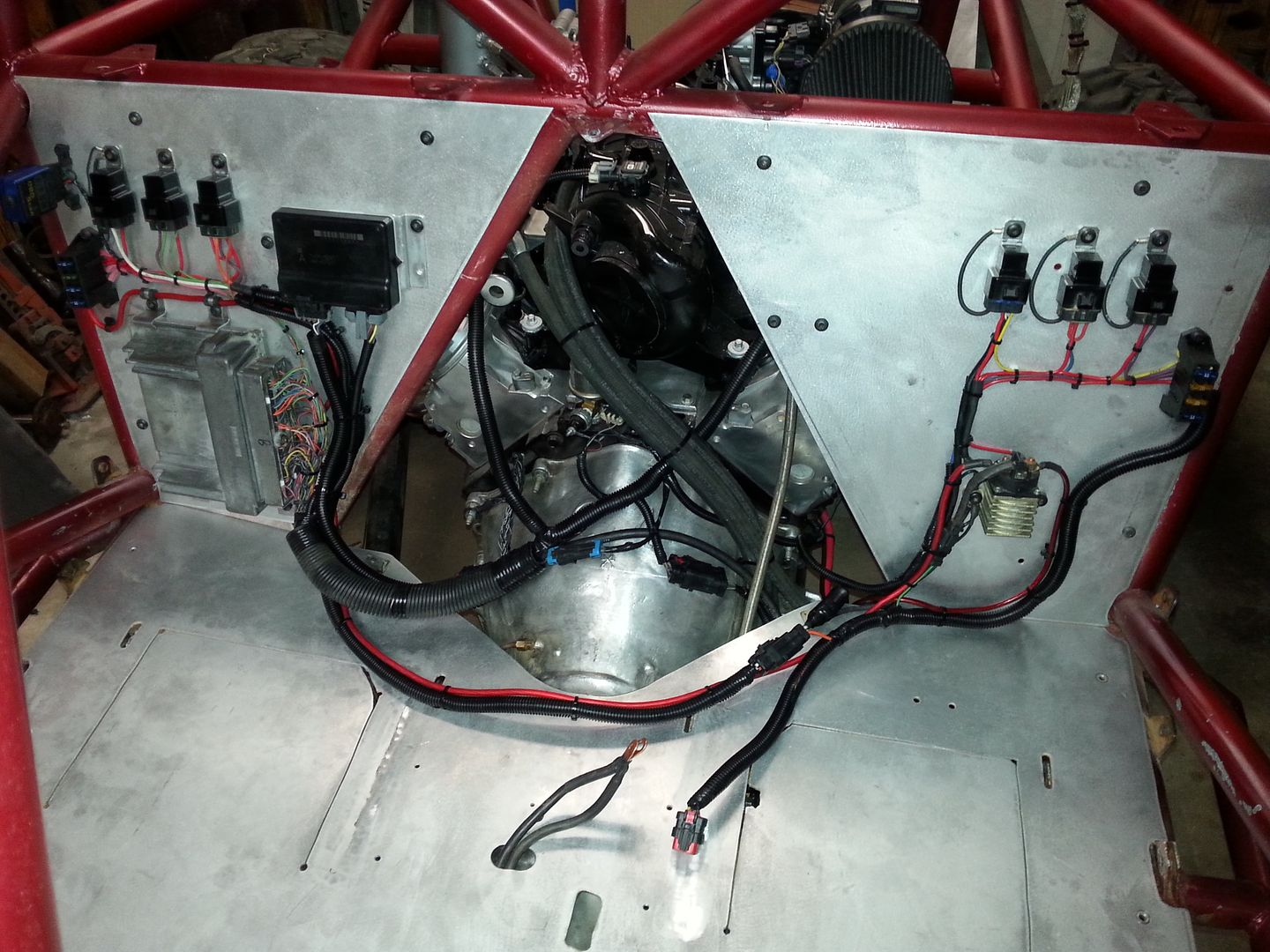

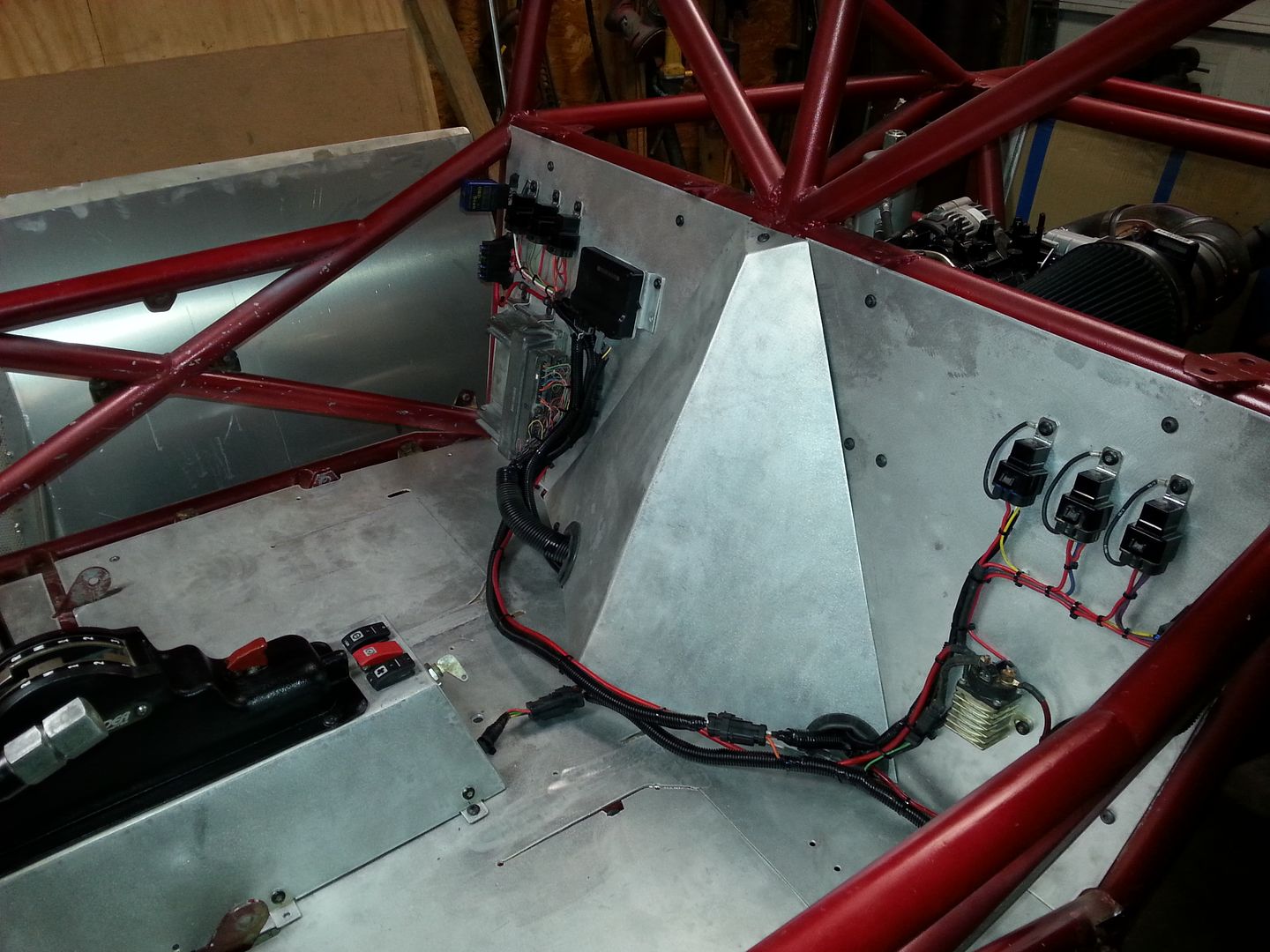

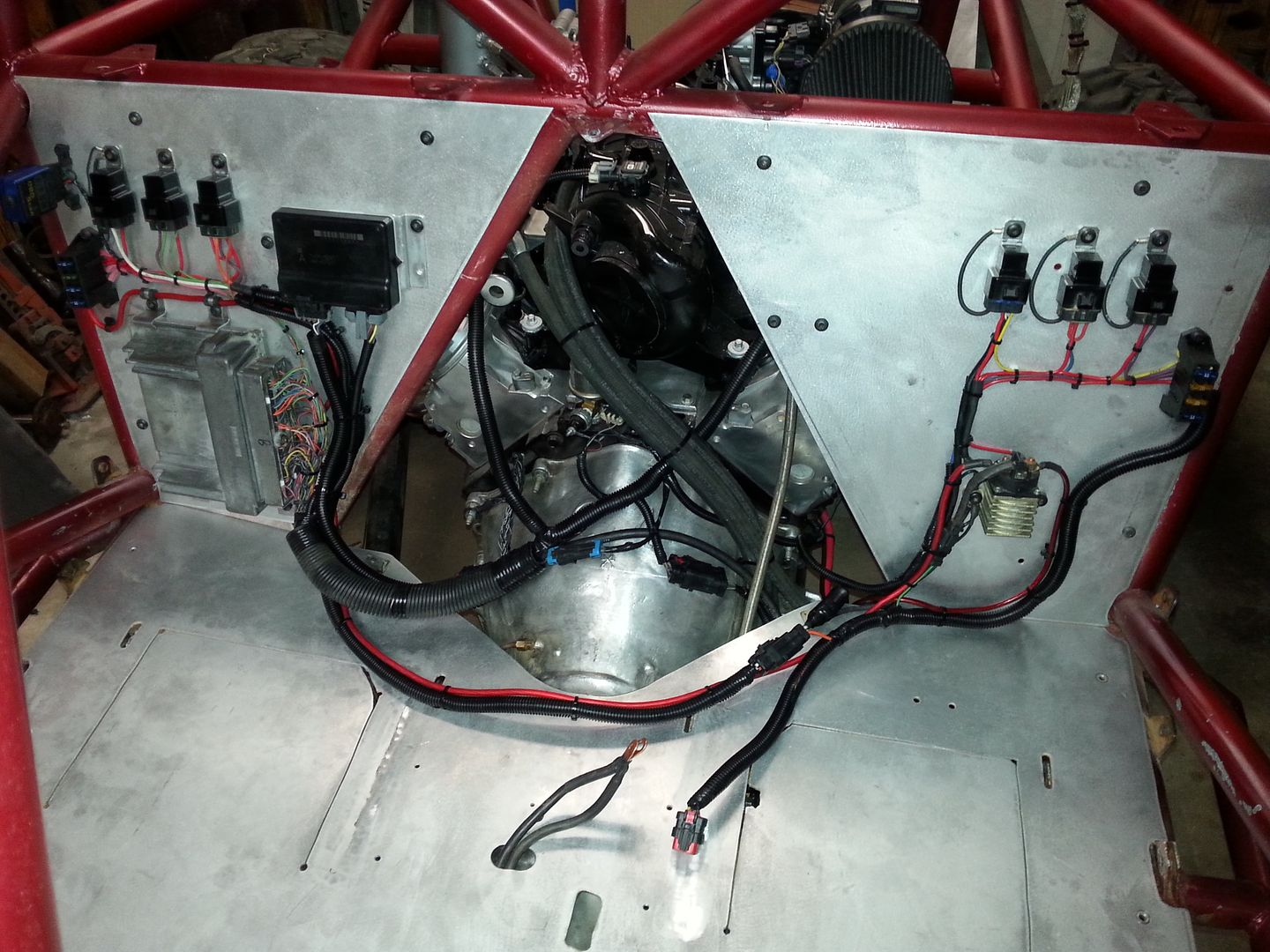

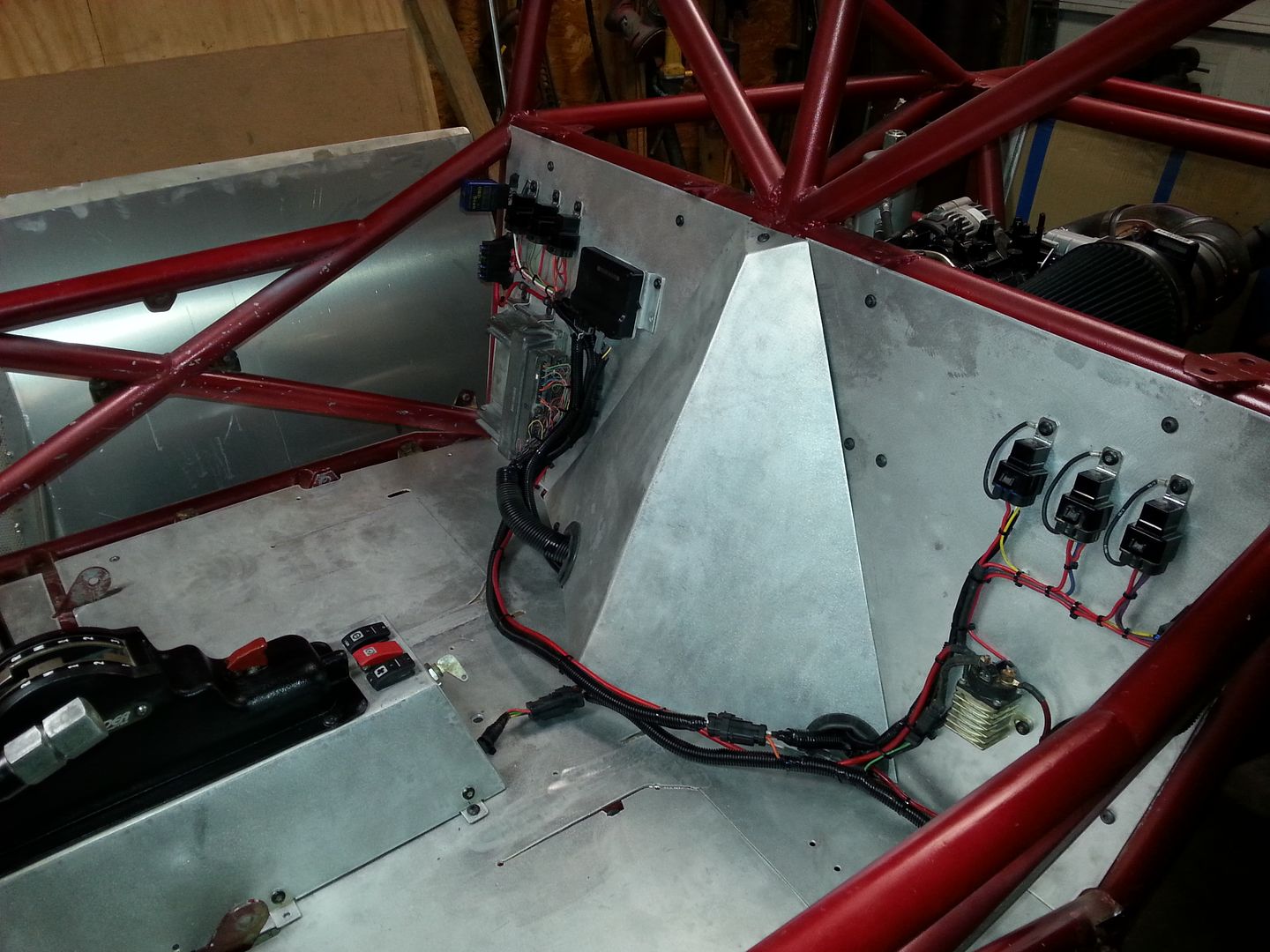

The wiring from before worked fine but not thought out enough when installed. This time around it was too hot to ride so I spent a couple of weeks doing wiring. I am happy with the results no extra connections than needed, all the circuits are color matching to the factory GM / LS harness. This will make trouble shooting the wiring a ton easier if needed since it matches the factory schematic. Fuses on all the signal wires to the relays and ECM.

I like having the ECM control the 2 fan speeds as well, one less thing for me to worry about.

I like having the ECM control the 2 fan speeds as well, one less thing for me to worry about.