-

Help Support Hardline Crawlers :

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pro Rock Stock Class XJ Build

- Thread starter MonnlightRacing77

- Start date

extremetownie

Well-Known Member

- Joined

- Apr 7, 2009

- Messages

- 707

- Reaction score

- 199

About 6 weeks . You ready to this.

MonnlightRacing77

When in Doubt Throttle Out

Waiting on shocks that and inner axles.i've been building and waiting on parts.I'll be ready

MonnlightRacing77

When in Doubt Throttle Out

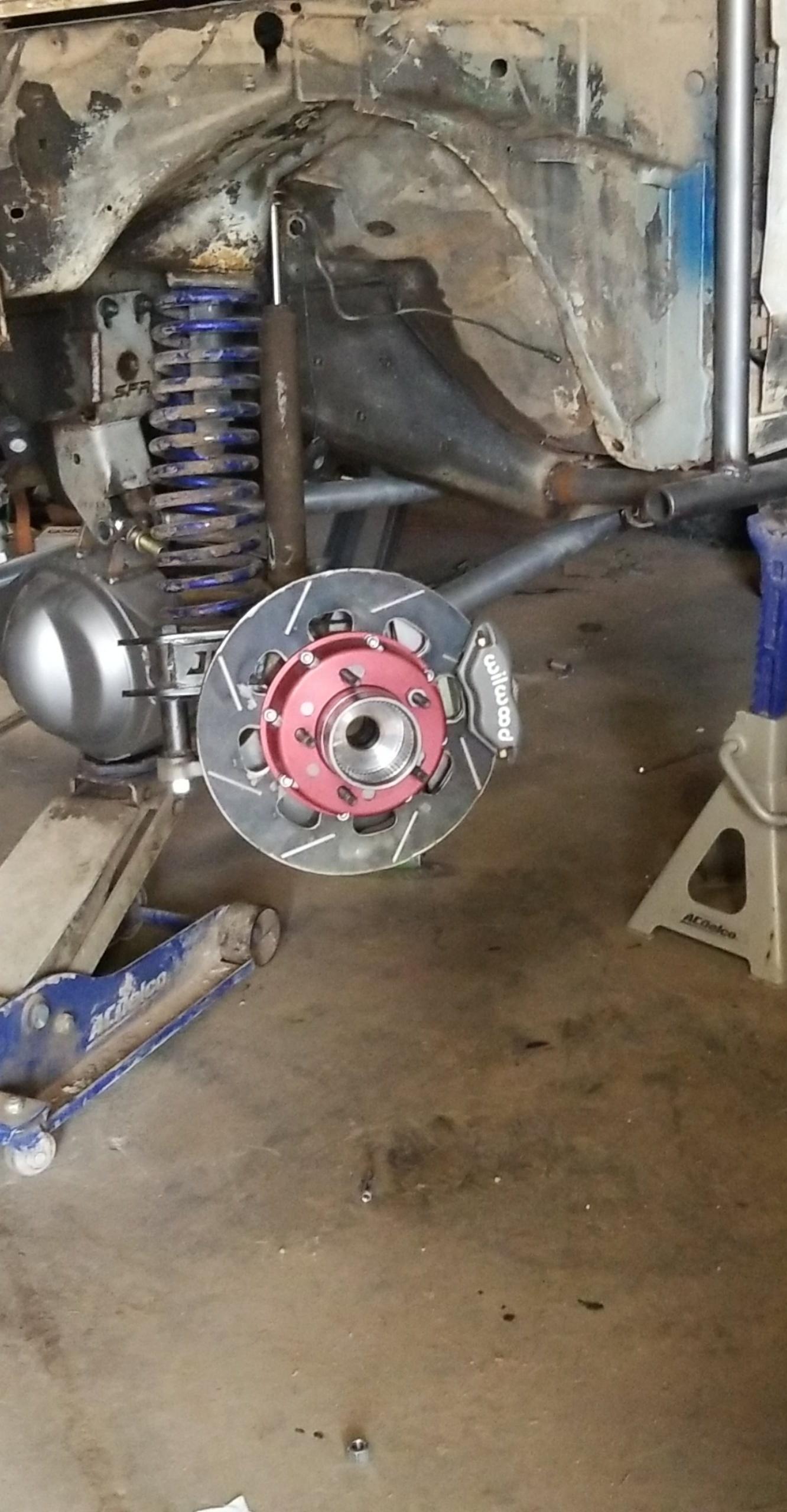

Ready to drill the hubs for studs and bored for 35 spline stubs

MonnlightRacing77

When in Doubt Throttle Out

Laid down some paint on the cage today.Really like this steel-it silver.And was able to get a tire bolted on.Man it's nice seeing this thing come together

MonnlightRacing77

When in Doubt Throttle Out

PCI 50w race communications came in and was told the bypasses have shipped from king

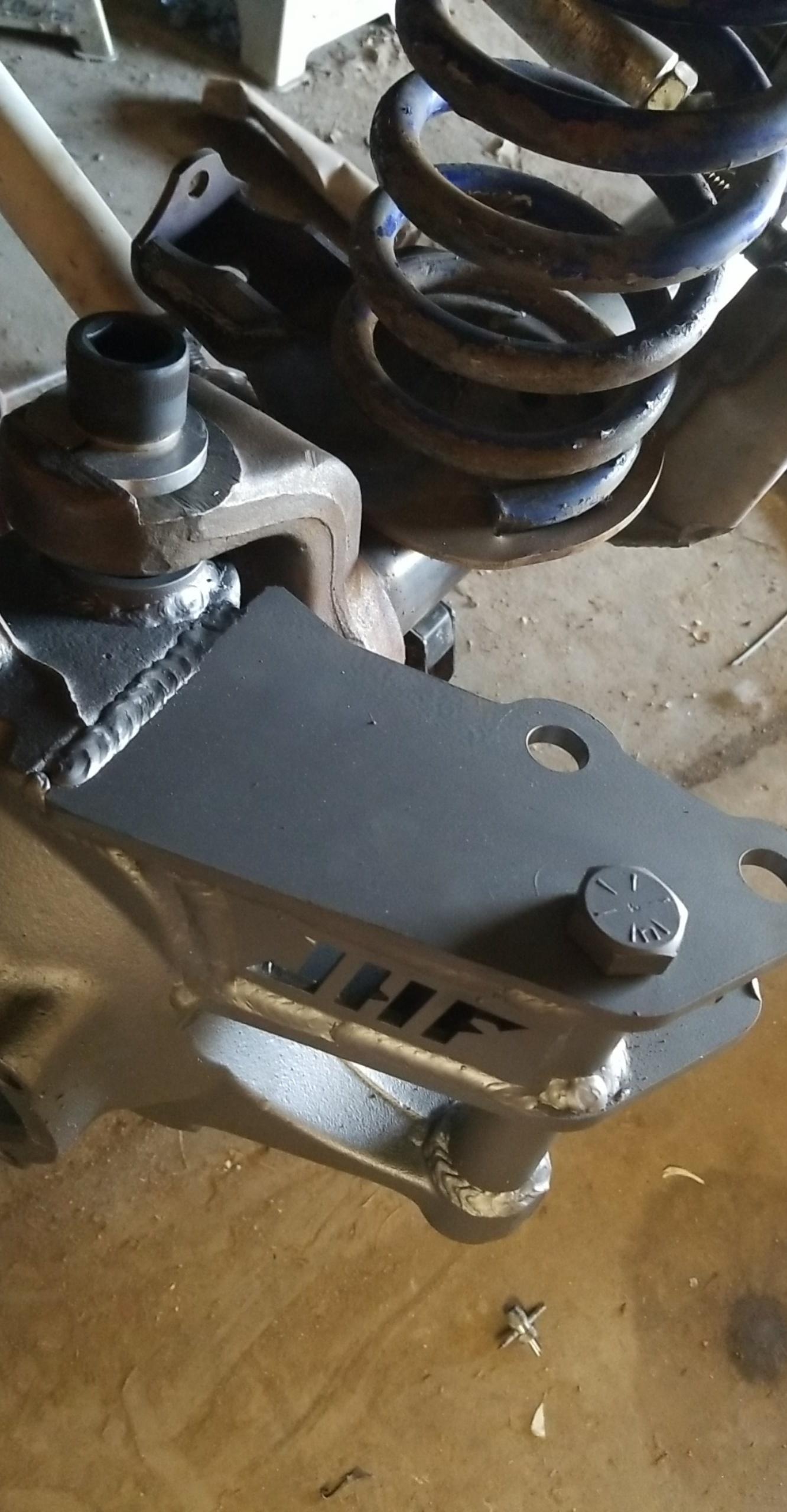

Worked getting upper link tabs built.The 2.25in lowers were definitely worth the price over the old 1.75 lower that will now be the uppers

Worked getting upper link tabs built.The 2.25in lowers were definitely worth the price over the old 1.75 lower that will now be the uppers

MoparMan

Well-Known Member

Man I'm really digging this build. This is gonna be one badass XJ!

MonnlightRacing77

When in Doubt Throttle Out

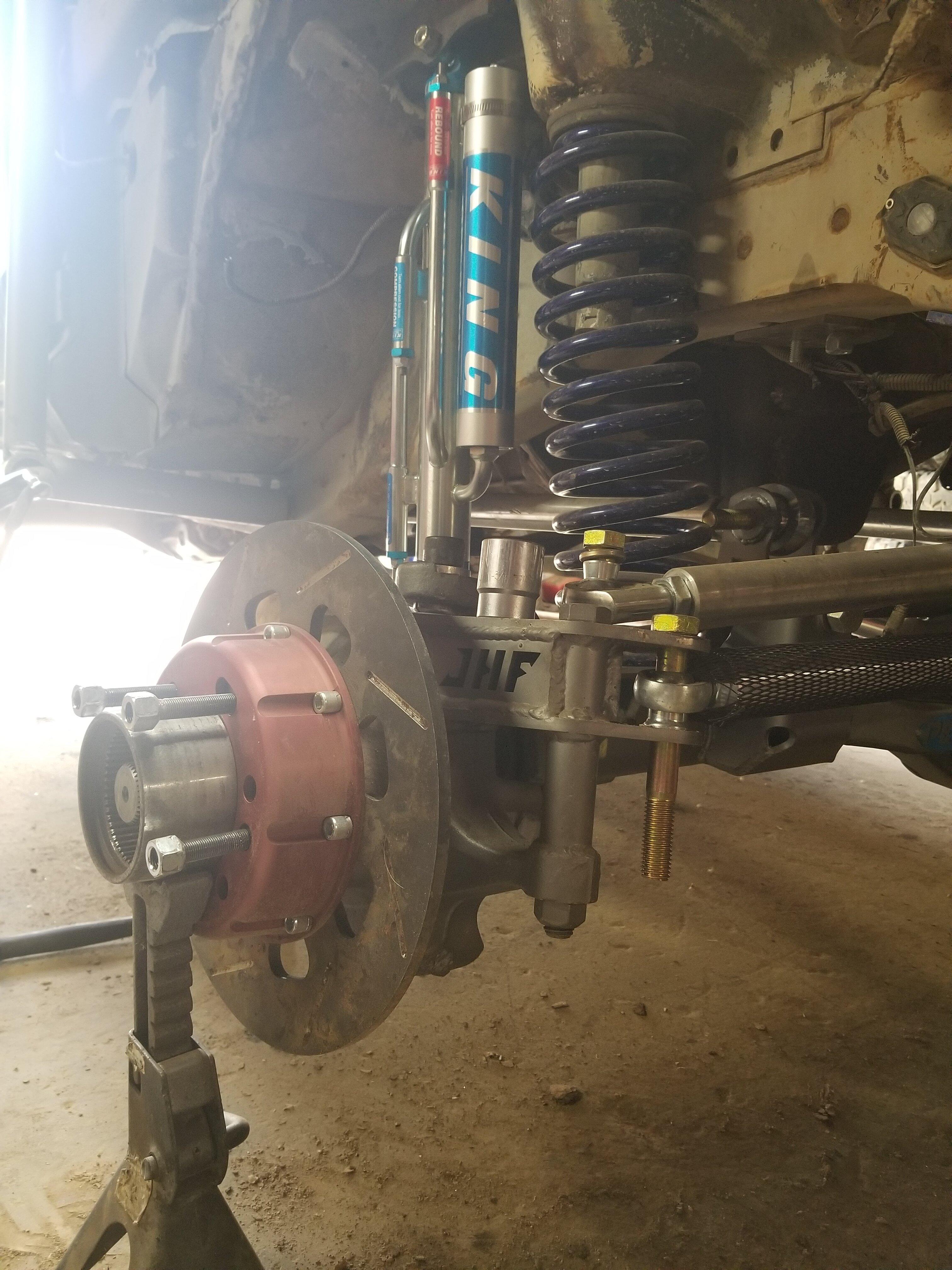

Bypasses came in. 2.0x12 3 tube piggy backs kings.Jeep is going to ride smooth

MonnlightRacing77

When in Doubt Throttle Out

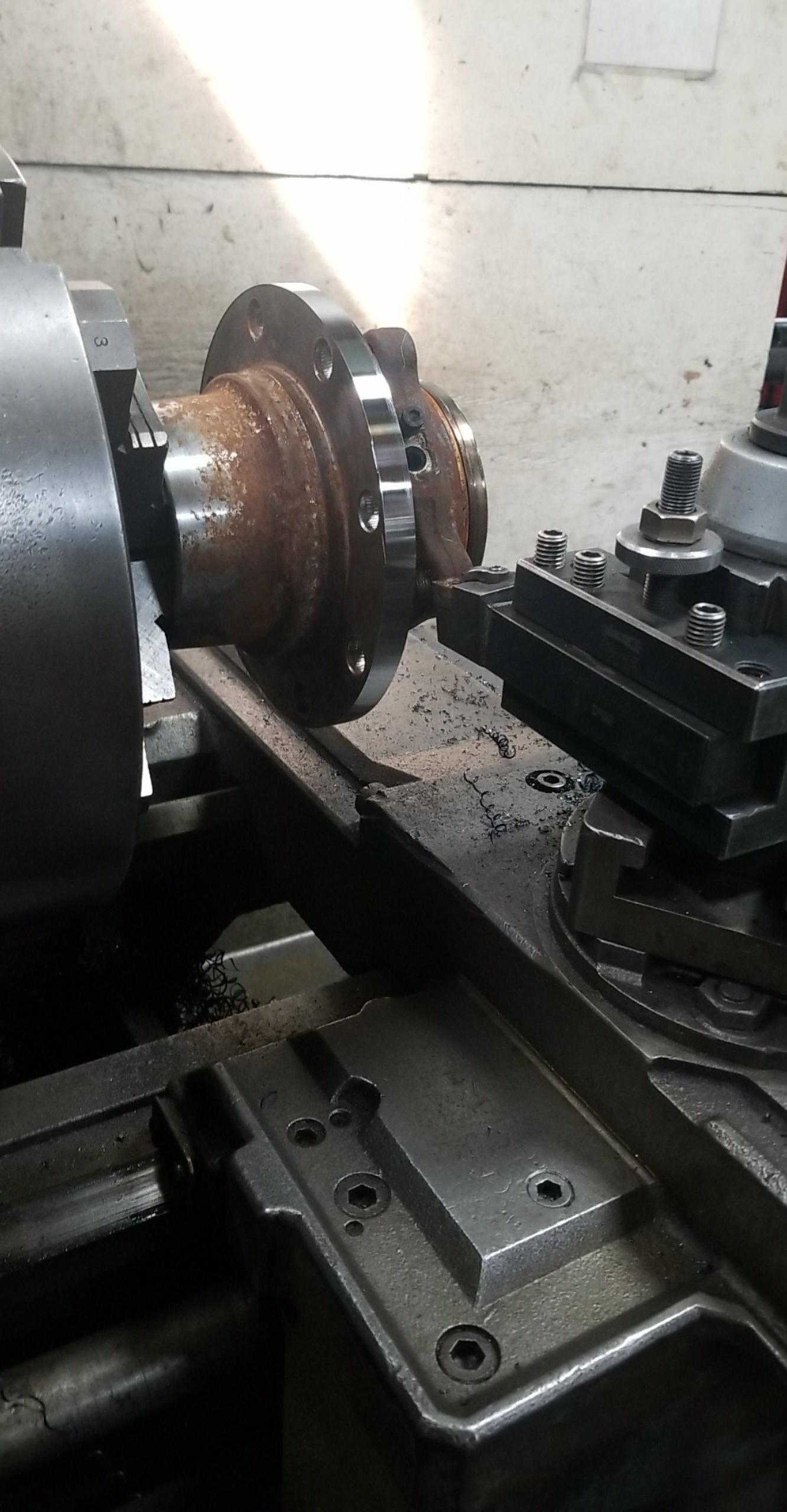

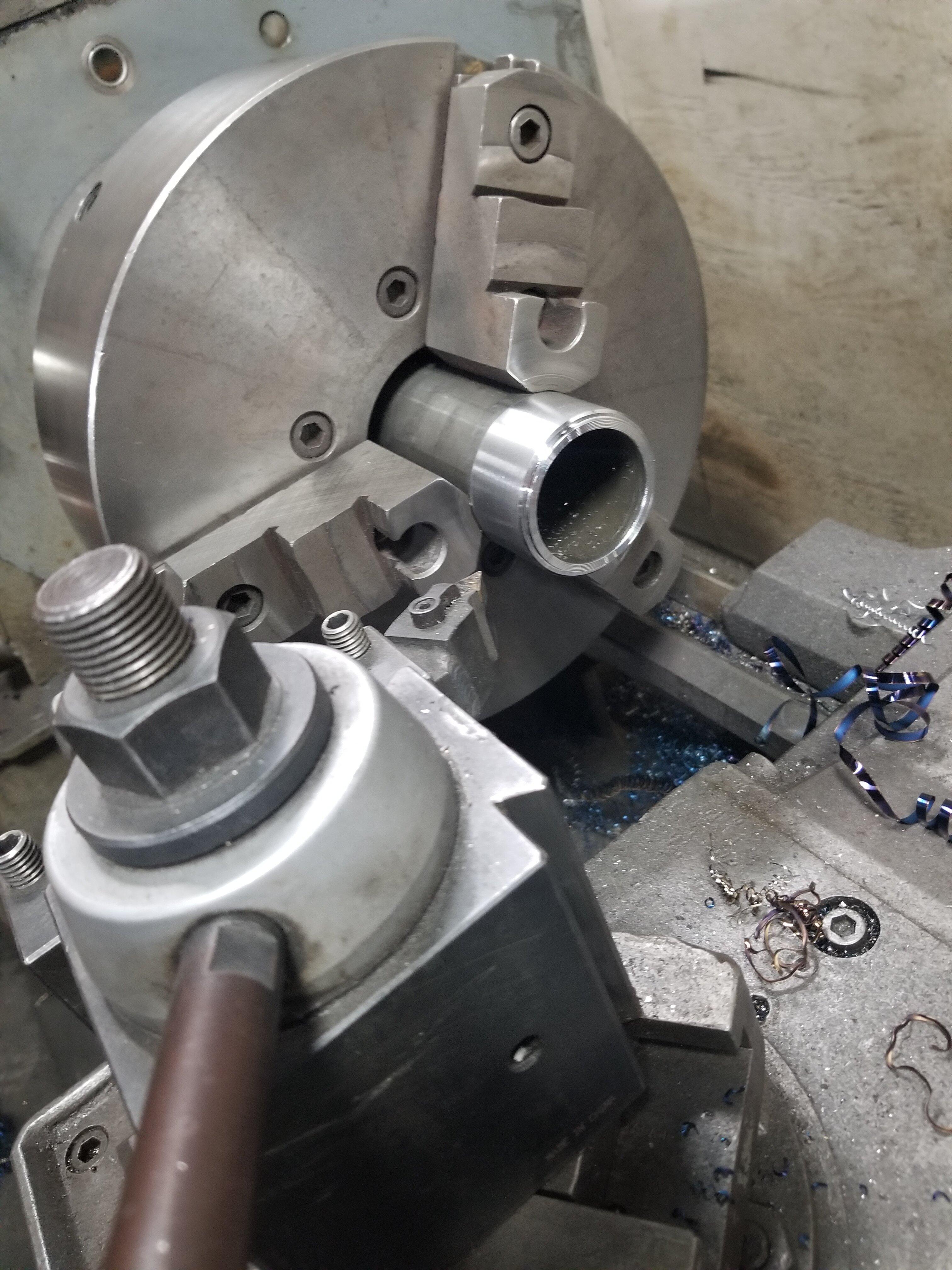

Well not much progress. Found a new timken bearing at the junkyard.Machined down today.

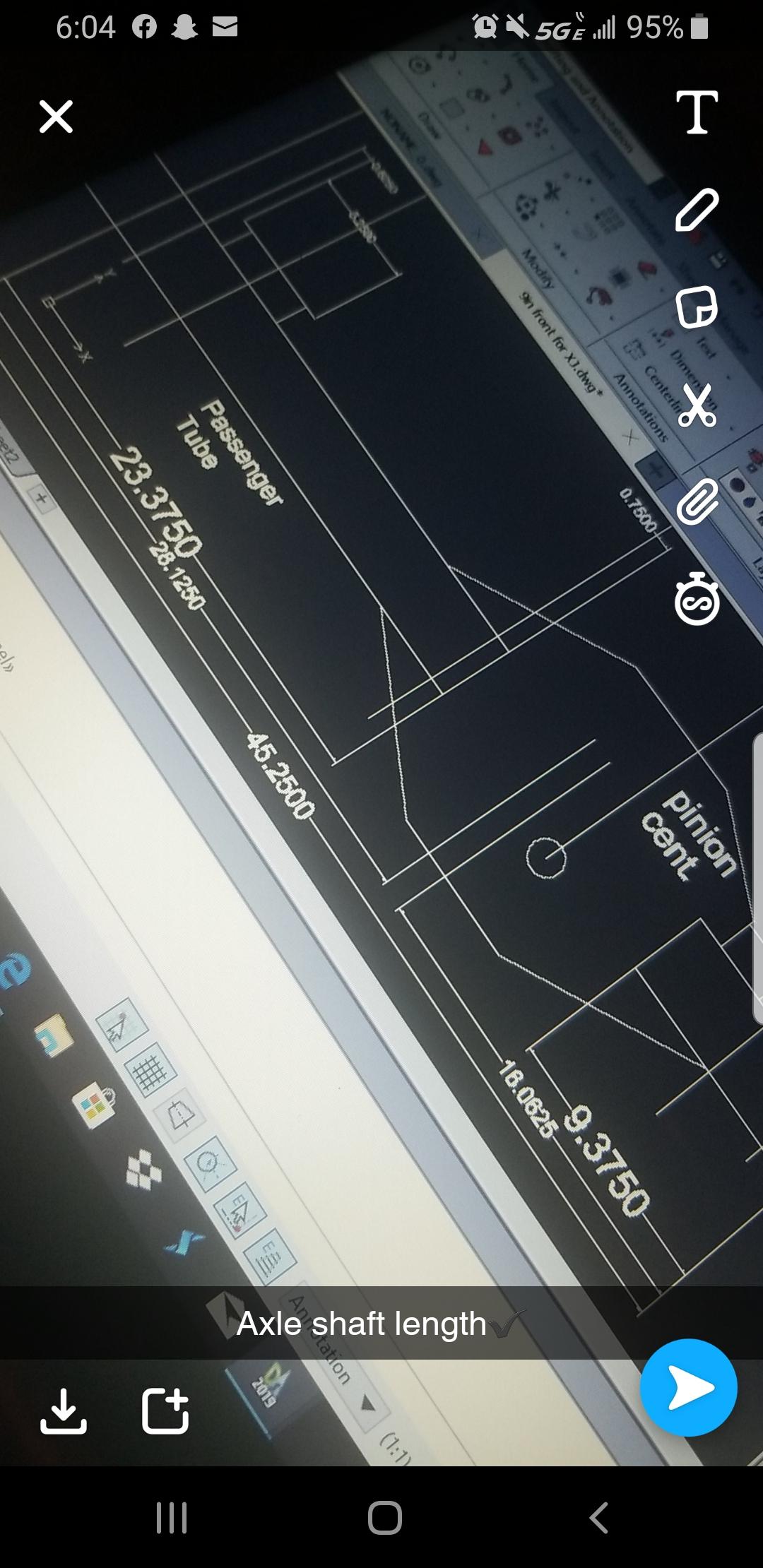

also was able to measure for inner axle shaft for dutchman to cut me some Foote shafts.Might short side inner is the same as a 79 ford short side inner.Which will be nice for a spare if needed

also was able to measure for inner axle shaft for dutchman to cut me some Foote shafts.Might short side inner is the same as a 79 ford short side inner.Which will be nice for a spare if needed

MonnlightRacing77

When in Doubt Throttle Out

A one week turnaround on inner axles from dutchman Axle. Made in the USA foote shafts.

Lil ugly

Well-Known Member

How did you prep for the paint on cage. I cleaned real well but i did not use a 60 grit like was suggested and the paint scratched easier than I like. I think it is because i left the metal too smooth. Looking for a comparison.

MonnlightRacing77

When in Doubt Throttle Out

I just wiped it done a few time ls with acetone and sprayed.Layed 3 coats down came out nice.

Lil ugly

Well-Known Member

Thats about what i did. It looks good but seems to scratch easier than i thought it would. It is nice being able to weld thru it though.

MonnlightRacing77

When in Doubt Throttle Out

Yeah I already welded a joint I missed and welded out the high steer arm on the a painted knuckle couldn't even tell it was paintedThats about what i did. It looks good but seems to scratch easier than i thought it would. It is nice being able to weld thru it though.

MonnlightRacing77

When in Doubt Throttle Out

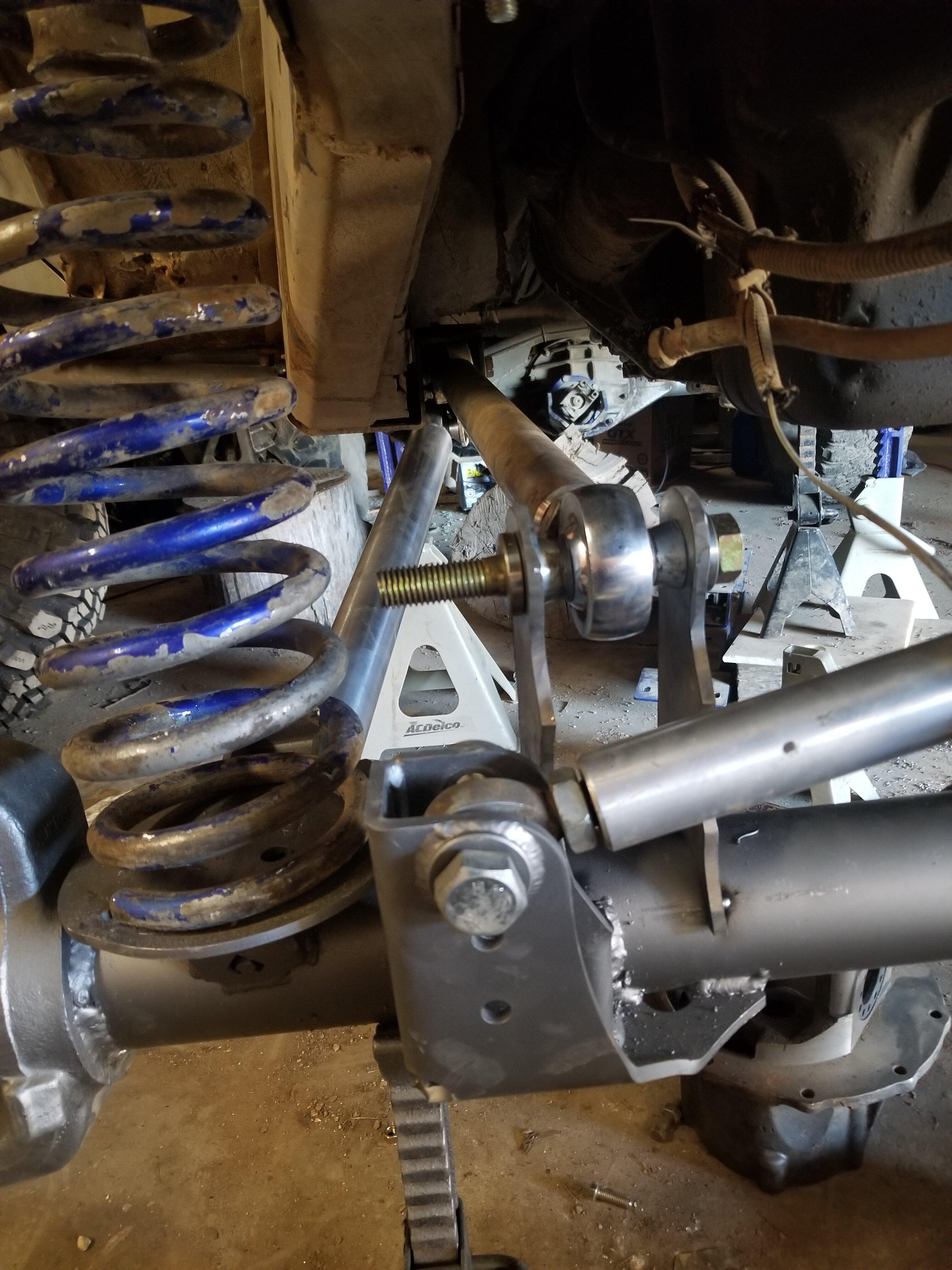

Finally got it mounted on all 4s for mock up and clearance check.Going to have to cut all the links down a .5in to 1in to get coils straighter. With that final tear down has commenced.

I can say one thing I cannot wait to see how good this thing stops.

I can say one thing I cannot wait to see how good this thing stops.

MonnlightRacing77

When in Doubt Throttle Out

MonnlightRacing77

When in Doubt Throttle Out

MonnlightRacing77

When in Doubt Throttle Out

Finally rolled out of the shop into the light for the first time since November.Steering is about buttoned up with the aluminum from wide open design.

Really like the stance on this thing.Low and wide.Most of the driveshafts parts are here but the stubs were on back order for a week. With the JK tcase having 32 spline output.Big CVs were an option with that being said 1410 Double Cardon from Neapco (N924141) made for 2.5in x .120 and flanges are what I went with these things are massive.

1310 and a 1350

in the midde.

Next came mounting the bypasses were I wanted them with around 50/50 up and down travel. Ended up with 6.5in UP and 5.5 down.Should be able to handle some whoops real well

Really like the stance on this thing.Low and wide.Most of the driveshafts parts are here but the stubs were on back order for a week. With the JK tcase having 32 spline output.Big CVs were an option with that being said 1410 Double Cardon from Neapco (N924141) made for 2.5in x .120 and flanges are what I went with these things are massive.

1310 and a 1350

in the midde.

Next came mounting the bypasses were I wanted them with around 50/50 up and down travel. Ended up with 6.5in UP and 5.5 down.Should be able to handle some whoops real well

MonnlightRacing77

When in Doubt Throttle Out

Started on driveshafts today.Should finish them up in the morning. The CVs and stubs are machined for 2.5x.120 wall from neapco.Chucked them up and now they are ready for .250wall.

Neapco has a nice line of long full spline slips in both 1.375 and 1.5 16 options.With slips to match

Neapco has a nice line of long full spline slips in both 1.375 and 1.5 16 options.With slips to match

extremetownie

Well-Known Member

- Joined

- Apr 7, 2009

- Messages

- 707

- Reaction score

- 199

I hope you know ,you are making me want to burn my cherokee and start over.