patooyee

Well-Known Member

- Joined

- Sep 27, 2008

- Messages

- 5,692

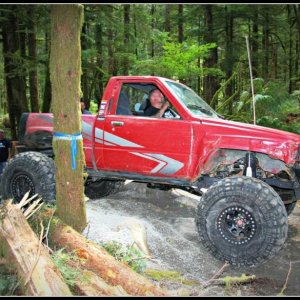

I am at an impasse of self-inflicted mind-**** right now and need some opinions. My LS2 fuel system has had constant issues since its first build.

First I did what everyone one Pirate did with the pickup in the tank, multiple Walbro pickups inside the cell connected to the fuel pump via. the special $38/ft fuel-safe rubber hose. The hose sucked shut, causing the really expensive Bosch pump to run dry and self-destruct the first trip out.

So I redid everything using ALL hard suction lines, this time using an Airtex pump. (Mainly because they ar readily available at stores, whereas the Bosch is not.) I was also kind of sketch about the tiny nozzle size of the Walbro pickups so I used all dual-outlet pickups, plumbing the duals into larger single lines so as to alleviate any possible bottleneck there. So now instead of sucking fuel through one 5/16 nozzle at each pickup it is doing so through two 5/16 nozzles. (I later found out that this is one of those tricks that KOH guys on Pirate use but do not post. : ) At the same time I moved my fuel cell to behind the radiator.

) At the same time I moved my fuel cell to behind the radiator.

This fuel system seemed to work for a while during the winter until it got hot during the summer. During the winter period that it worked I suffered 3 stuck injectors on separate cylinders and occasions. While annoying, they didn't damage the engine, just my wheeling time.

But once the Florida summer came I found that the fuel was overheating causing a vapor lock somewhere. First I figured the heat was getting into the system from a fuel cooler I had mounted remotely close to the exhaust. So I wrapped the exhaust, no improvement. I built a heat shield for the exhaust, no improvement. I removed the cooler altogether, no improvement. I used heat-shielded ceramaic hose to cover ALL fuel lines in the engine compartment, no improvement. The last place I figured was heat blowing from the rad onto the fuel cell but by this point fuel pump #2 was toast. After replacing the pump again I built a heat shield between the rad and the fan. Its very close to the cell because I just don't have much space, but there was no improvement there either. As a last ditch experiment I decided to reverse the radiator fan to blow onto me instead of at the cell, problem solved.

So now the issue is that I don't like the fan blowing at me. Not only does it make an already hot cab hotter, it runs more often since it is not as efficient. With the fan spinning the correct direction I can hammer down non-stop as long as I want and it never gets hotter than 210. I am not confident enough to do that with it spinning the wrong way. In addition, my fuel cell is kind of small and I would like bigger. Problem with that is that I ahve to completely redo all my rear section of tube work to do that. At the same time, I can build a better shroud for my fan to direct it away from the fuel cell.

BUT, to be perfectly honest, I'm just sick and tired of issues with gasoline. I think back to my propane days and how simple things were. I know I can eliminate pumps, injectors, multiple sensors, and lots of wiring if I just switch to a carbed manifold and do propane again. In addition, the carb manifold produces more power than the stock manifold. I think I can do some engine upgrades I've been wanting to do without having to dyno tune if I switch to propane and I won't need to spend money on new injectors, either. I already have dual 425 mixers sitting on the shelf.

Yet it just seems so sacrilegious to rip the EFI off an all-aluminum motor to put 2 carbs on top. I also know that the buggy is worth more someday should I sell if it runs on gas. But either option requires redoing my rear tube work, so that is just something I've resigned myself to.

So what say you? Keep spending on gas with lots of sensors, wires, injectors and pumps that are prone to fail or do super-simple propane which I know and love?

First I did what everyone one Pirate did with the pickup in the tank, multiple Walbro pickups inside the cell connected to the fuel pump via. the special $38/ft fuel-safe rubber hose. The hose sucked shut, causing the really expensive Bosch pump to run dry and self-destruct the first trip out.

So I redid everything using ALL hard suction lines, this time using an Airtex pump. (Mainly because they ar readily available at stores, whereas the Bosch is not.) I was also kind of sketch about the tiny nozzle size of the Walbro pickups so I used all dual-outlet pickups, plumbing the duals into larger single lines so as to alleviate any possible bottleneck there. So now instead of sucking fuel through one 5/16 nozzle at each pickup it is doing so through two 5/16 nozzles. (I later found out that this is one of those tricks that KOH guys on Pirate use but do not post. :

This fuel system seemed to work for a while during the winter until it got hot during the summer. During the winter period that it worked I suffered 3 stuck injectors on separate cylinders and occasions. While annoying, they didn't damage the engine, just my wheeling time.

But once the Florida summer came I found that the fuel was overheating causing a vapor lock somewhere. First I figured the heat was getting into the system from a fuel cooler I had mounted remotely close to the exhaust. So I wrapped the exhaust, no improvement. I built a heat shield for the exhaust, no improvement. I removed the cooler altogether, no improvement. I used heat-shielded ceramaic hose to cover ALL fuel lines in the engine compartment, no improvement. The last place I figured was heat blowing from the rad onto the fuel cell but by this point fuel pump #2 was toast. After replacing the pump again I built a heat shield between the rad and the fan. Its very close to the cell because I just don't have much space, but there was no improvement there either. As a last ditch experiment I decided to reverse the radiator fan to blow onto me instead of at the cell, problem solved.

So now the issue is that I don't like the fan blowing at me. Not only does it make an already hot cab hotter, it runs more often since it is not as efficient. With the fan spinning the correct direction I can hammer down non-stop as long as I want and it never gets hotter than 210. I am not confident enough to do that with it spinning the wrong way. In addition, my fuel cell is kind of small and I would like bigger. Problem with that is that I ahve to completely redo all my rear section of tube work to do that. At the same time, I can build a better shroud for my fan to direct it away from the fuel cell.

BUT, to be perfectly honest, I'm just sick and tired of issues with gasoline. I think back to my propane days and how simple things were. I know I can eliminate pumps, injectors, multiple sensors, and lots of wiring if I just switch to a carbed manifold and do propane again. In addition, the carb manifold produces more power than the stock manifold. I think I can do some engine upgrades I've been wanting to do without having to dyno tune if I switch to propane and I won't need to spend money on new injectors, either. I already have dual 425 mixers sitting on the shelf.

Yet it just seems so sacrilegious to rip the EFI off an all-aluminum motor to put 2 carbs on top. I also know that the buggy is worth more someday should I sell if it runs on gas. But either option requires redoing my rear tube work, so that is just something I've resigned myself to.

So what say you? Keep spending on gas with lots of sensors, wires, injectors and pumps that are prone to fail or do super-simple propane which I know and love?