CHOP SHOP

Well-Known Member

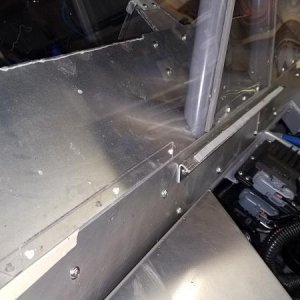

If it sticks together its weldable right:eeek::haha: Nice lookin bang for your buck build brad:awesomework:

I even put the serial number stamped in ^up^ to see if you guys would catch that.:kissmyass: It makes me feel good to see you guys look so close at my ghetto fab.:haha:

It helped it fit on the diff allot better. :awesomework:

Its ok its a DOM handrail corner.:beer: