Im surprised none else has anything to say

Weld in bungs...

work looks great though:beer:

Im surprised none else has anything to say

Im surprised none else has anything to say

Thanks man,I appreciate it.This thing is taking forever but im trying to cover all the lil details and make stuff nice.

Im surprised none else has anything to say,maYbe its just to much overkill for some taste.i like over kill.lol:awesomework:

Weld in bungs...uke:

work looks great though:beer:

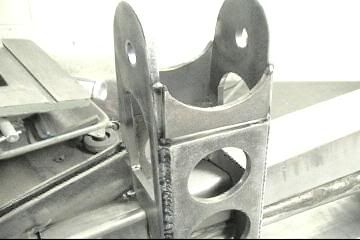

Your over kill will most likely give you a "happy" housing.... Good luck keeping seals in that front diff when your done :;. and X2 on the comment from Mall'er... that upper link mount on the housing is going to collapse. I PROMISE! :awesomework: Adding stringth with effiecinecy not just throwing metal at it because it looks cool! On a good note your fitting and fab (bracketry) looks great but you need welding practice. would you like me to continue? :flipoff:

Please do.[/quote]would you like me to continue? :flipoff:

Please do.

I would re investigate your axle truss... is it really needed and ask yourself is that where they bend? I seem to remember it being right next to the socket where it attaches into the housing... (which is why they make stiffiners for that application) than there is always starting with a better axle in the first place.... like maybe a 60 and not put a ton of money into something you will not get **** for in the long run saving yourself money and time down the road. :flipoff::redneck: it really does not need the brace like you have added... it does not make it bad ass it makes it an "extra heavy" tuna can now. you shockmounts are so overkill... it's just a shock. you over engineered the hell out of them for a light rig. all that girth for a little 1/2" bolt. stay with the light theme it will be more reliable in the long run. hopefully you wll be thinking more (efficient) when you build your cage. gawd forbid you would roll... you'd have running gear from a toyota weighing the same as rockwells and would squish the $hit out of ya!:; the only ppl your going to impress with this is an idiot that does not know the difference. All jabs and joking aside. you have skills for fabbing nice. just put the strength where it is needed and build efficiently. More tube or more metal does not mean stronger.

WOW Mike, sounds like this guy needs a tall glass of HATORADE, or a trip back to Pirate!

He's building a "wheeler" not a "full on comp buggy", not everybody can run 60's.

Keep up the good work Mike.

WOW Mike, sounds like this guy needs a tall glass of HATORADE, or a trip back to Pirate!

He's building a "wheeler" not a "full on comp buggy", not everybody can run 60's.

Keep up the good work Mike.

After you weld up that truss and mounts I would re-true that housing(housing jig and straighten housing).

There is no way after all of those added components and welding that housing will still be straight. But I have been wrong before.

I'm in on the top link on the axle too much meat taken out of the metal. I think it will bend.

Hold on there L2C, I'm glad to hear Jason's opinion. He's built more rigs, and has a good understanding of the physics and dynamics involved. You may think they're negative-biased, but the opinions sound pretty objective to me.

did you miss the part where I said "All jabs and joking aside"??? bottom line is I am offering advice. he asked. Is he doing a good job? YES it would be more "dickish" of me to just let him build as he is and let him **** up his housing and end up with a turd right out of the gate. It is no advantage to me to offer any advice. I am not offering it to feed my ego or to feel better about myself. I have nothing to porve to ANY ONE on this bord or anywhere. I am just trying to help someone save themselves money and parts. the point is if he wants heavy start with heavy and it will last.

I do not get out to wheel much but when I do the last thing I want to run into is some dude broken in the trail being a trail tampon. If I have the opertunity to help when asked I will so, And later I will not have to deal with some ****box blocking the trail. :;

This is one way you would think to handle it, but you cannot do that with the birf ends on that style front housing. the ends of the housing are machiened for the ends to slide in they are not a butt weld, but are a slight press fit. Even if this on a rear housing where you butt weld the ends on the deflection would be so much the ends would be more than 1" off not allowing the housing ends to align with the carrier.... How do I know? I have learned alot from screwing up in the past. people can either learn from my mistakes or they can learn from their own. the beauty of advice... you can take it or leave it.

I wasn't being all that serious about my coments, I guess the funny green guy with his junk doing the windmill wasn't clear enough for that!

..............................................................................................................................

After you weld up that truss and mounts I would re-true that housing(housing jig and straighten housing).

There is no way after all of those added components and welding that housing will still be straight. But I have been wrong before