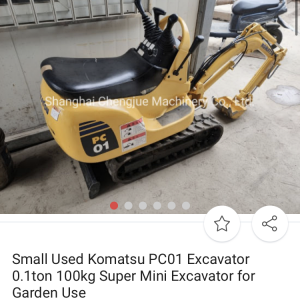

OK, so the York has to go somewhere else, like a different rig I guess. I'm thinking on my trailer with an small electric motor to drive it and a decent size air tank. I hear a portable shop being built on my trailer. I use the trailer to haul the kids quads around as well so having this setup on the trailer wouldn't be a bad thing anyway. I have a 12v power supply to the trailer and I'm putting a battery on there for a receiver mount winch anyway.

Move on past the compressor. I'll have to go the electric compressor route. Keep a location for an air tank in mind however, as well as wiring for the switch. I'll use the same setup as my 4Runner with a pressure switch.