Let me preface this by saying I just spent 10 hours in a cold, dark garage with 3 light bulbs and finished off every beer in the house. I'm a wee bit drunkish :redneck:

Well I started off thinking how this was a waste of gauge space

So I figured I could rework the bracket my summit gauges came in

I cut the top mounting surface so that it was only as deep as the other edges and temporarily bolted it to the dash.

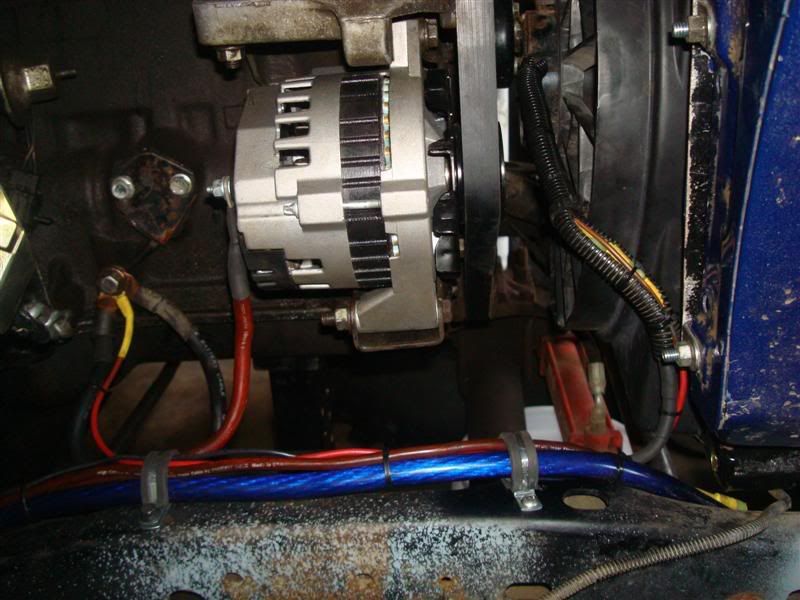

Now I've been racking my brain trying to figure the best way to mount my engine water temp sender. I've found two stock temp senders, but neither one has enough material around it to drill and tap for the larger new sender. So I got on Pirate for some research and decided to just go ahead and splice into a water return line. I figure this is only a few inches from one of the stock senders so even if the water pump failed, the water near this would heat up and trip the alarms... May change it down the road but it should be fine for now.

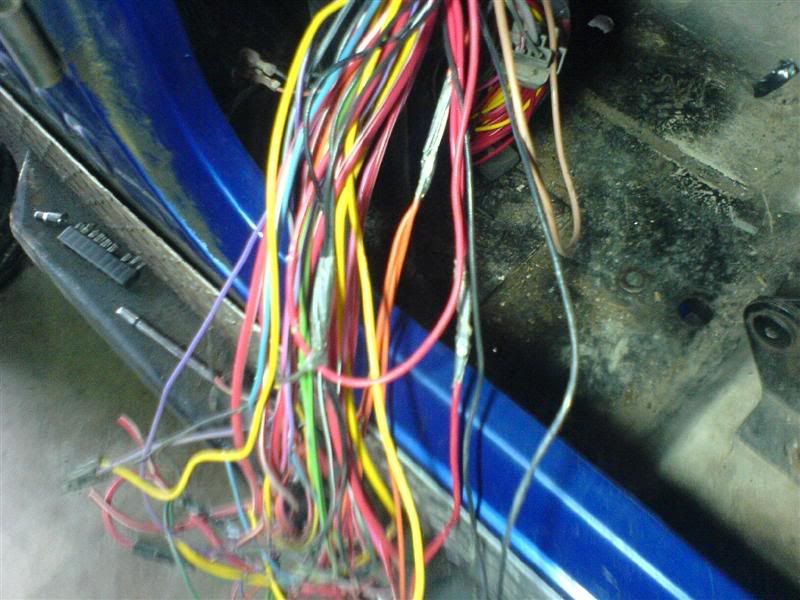

Then I got back to the wiring. Since I had to make this panel to cover the old speedo hole, I figured it'd be the perfect spot for a row of toggles.

My best crash impersonation

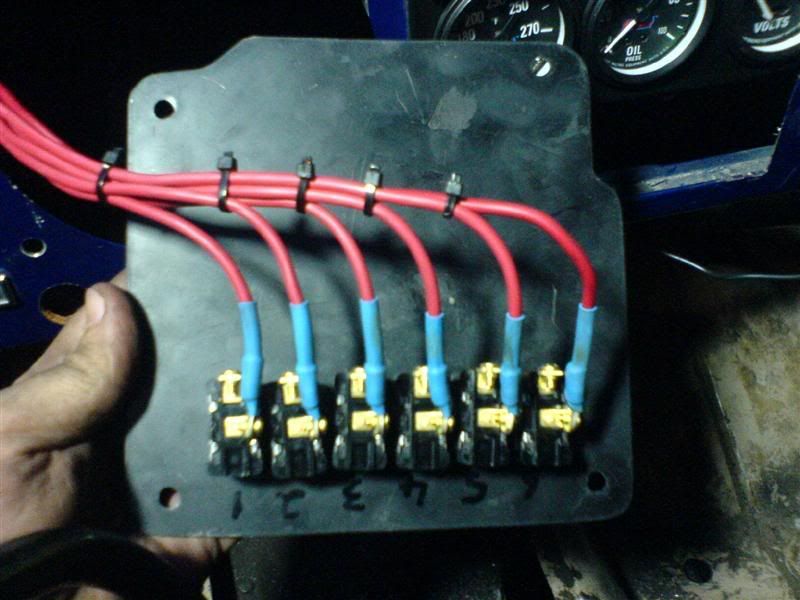

Picked up some nicer round headed bolts and stuck 'er in. From left to right:

1) Running lights

2) Headlights

3) Rock lights

4) empty

5) empty

6) Elec fan kill switch

Also wired all the gauges with spades so they're individually removable.

I know crash said he doesn't like this style fuse panel, but I figured since it was already bought, I'd try it. I'm kinda thinking I don't like it already... The spade connectors seem wiggly and chincy. I'm sure it'll work, but I think I'd like something with set screws for a more solid feel. Luckily I planned for such and event and left the wires a bit long.

I started to rewired the key switch, and now just need to get a solenoid for my fuse panel which will be triggered by the key. Also wired the propane solenoid into the fuse panel along with the new push button ignition switch. Then spent way too long upside down contorting myself reaching under the dash to wire-tie everything out of the way and together.