I redid my rock lights. Put the long narrows in the middle, moved one set of bullets to the front, and mounted the other set of bullets under my taillights for better lighting. Haven't hooked up wiring though. But after spending the afternoon/evening chillin at my buddy Brian's shop supervising him while he was redoing his rear links :redneck: I got re-energized to do my mounts.

No hole saw so it's grinder coping for me :booo:

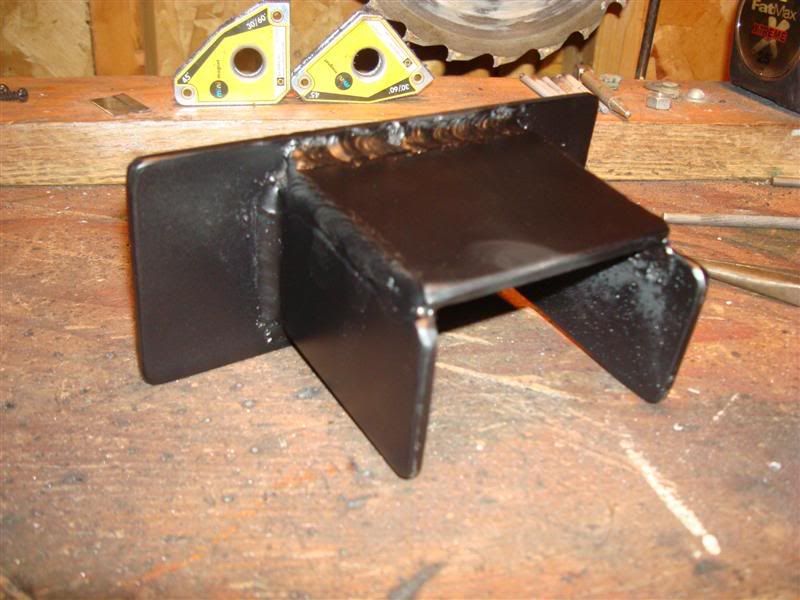

This would be my first time actually welding something structural with my stick. The phrase "monkey ****ing a football" comes to mind, but I burnt that bitch in. This hopefully will be my tranny mount.

FWIW, Cash likes to let the dog know exactly where she stands in the hierarchy :haha:

On to the engine side motor mounts. Not much better but it's a learning process...

How's my HAZ? :redneck:

Had to redo one of the tranny mounts for better fitting cause I didn't like where it ended up.

At least these resemble welds...

They ain't pretty. But ****'s burnt through so hopefully it'll hold up

Comments/suggestions on welding welcome... :hi: