InDaShop

Dont Tread On Me

JohnG said:He must know Adam

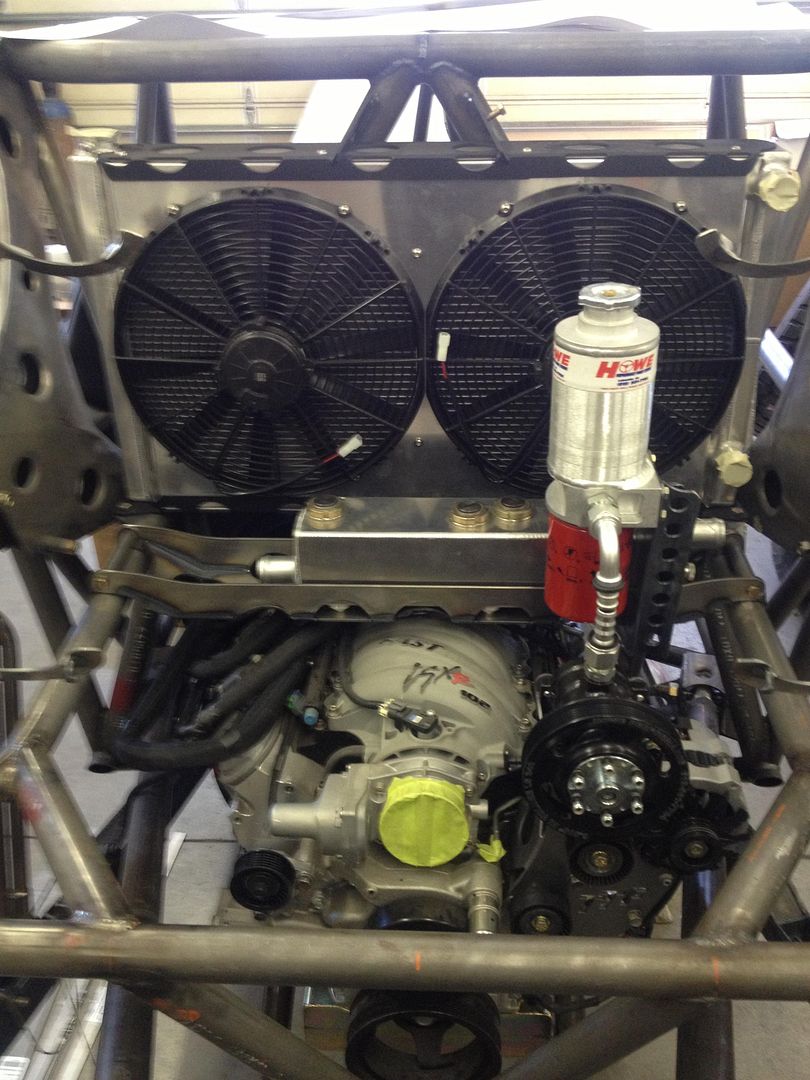

I've asked for pics, and he responds with "no". I was beginning to think he wasnt working on it. But I went out a month ago and sure enough hes busted serious ass.

JohnG said:He must know Adam

P said:Completely unrelated , but I'm AL bound next week to pick up the double nickel

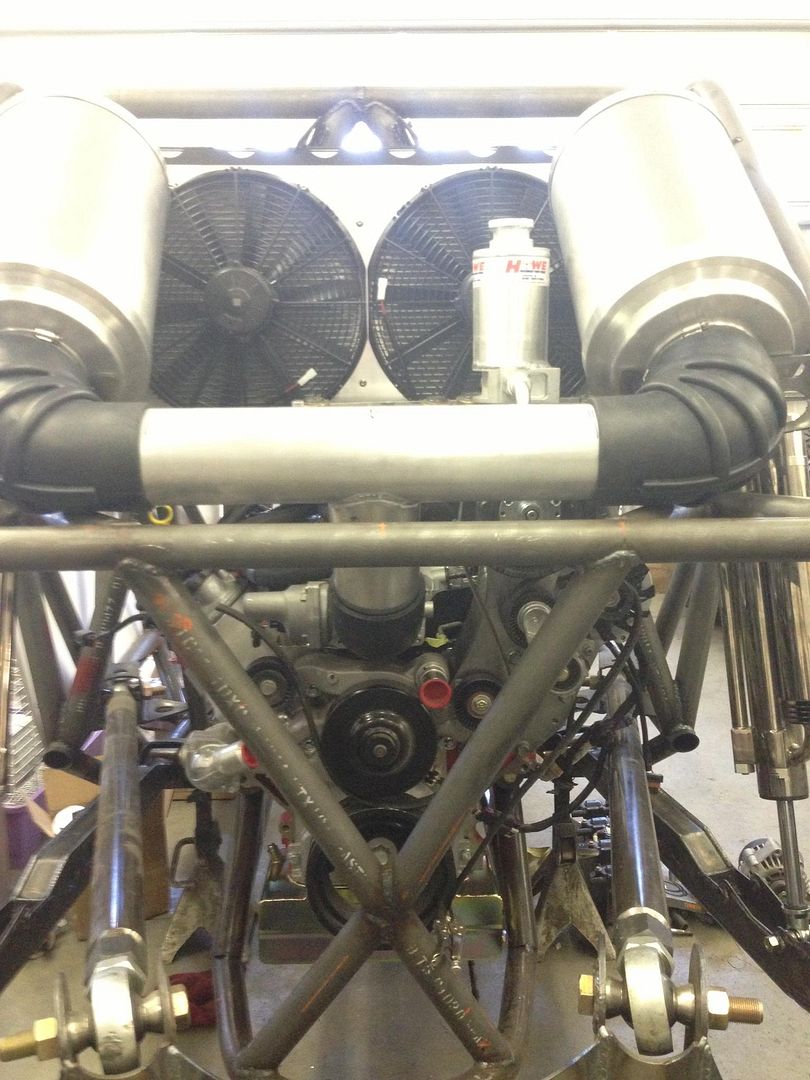

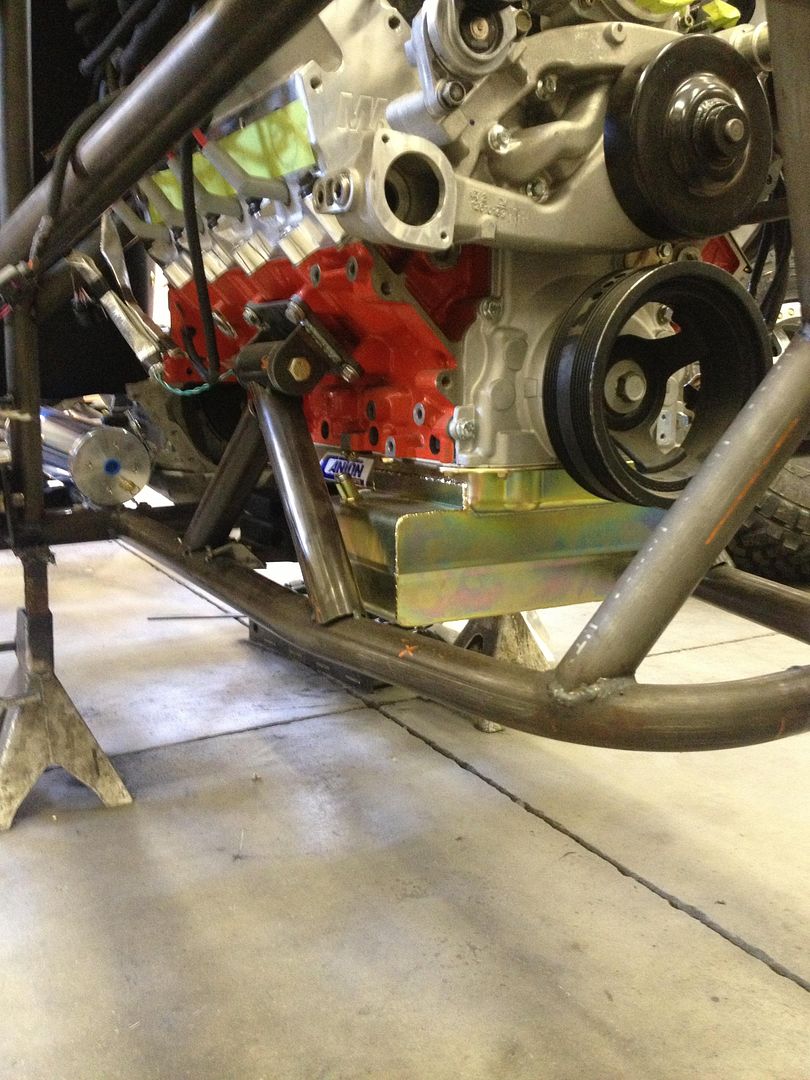

It'll probably be re done again before this unit. But then again its on tractor hiems and broken dreams for suspension

Travis said:It doesn't look like there is much triangulation on rear links. Even using quality heims, be prepared to replace them very frequently.

Might be the camera angle though.

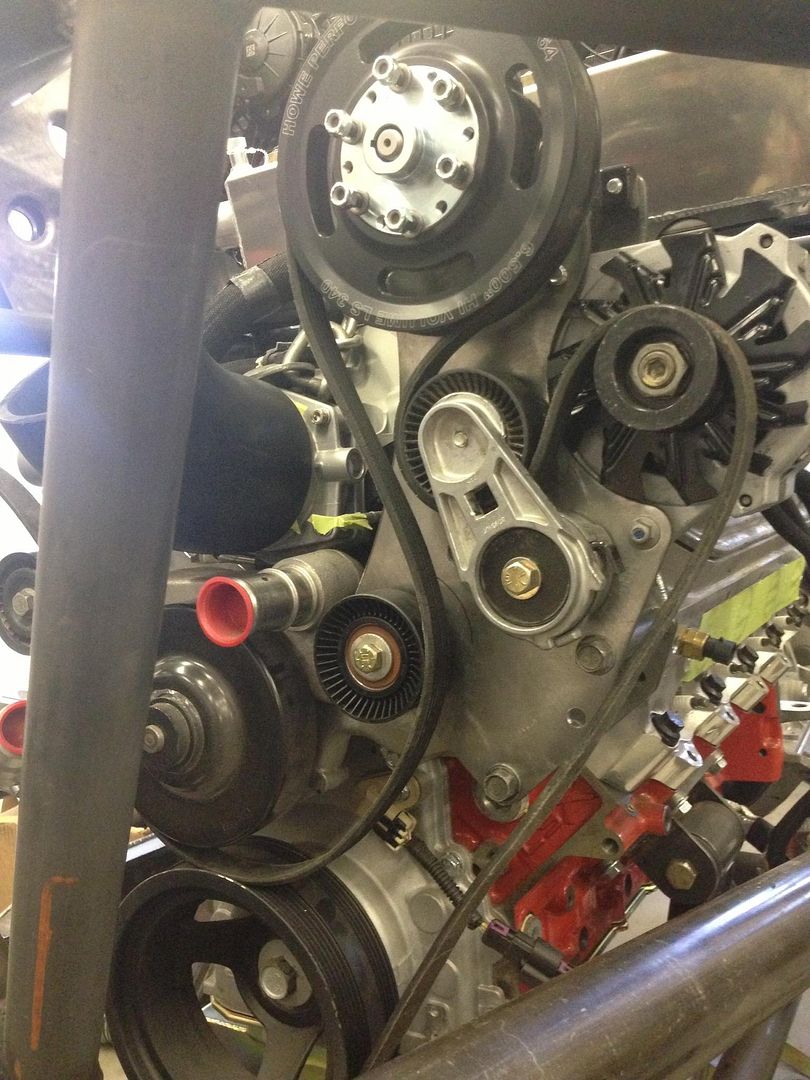

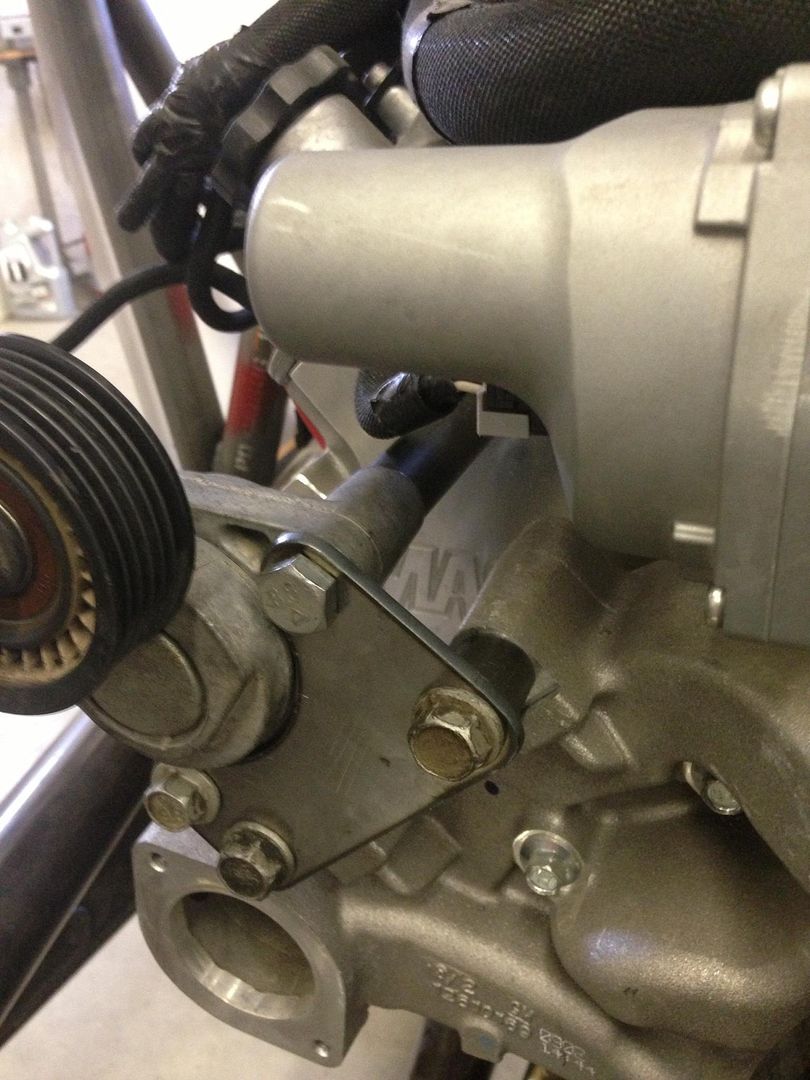

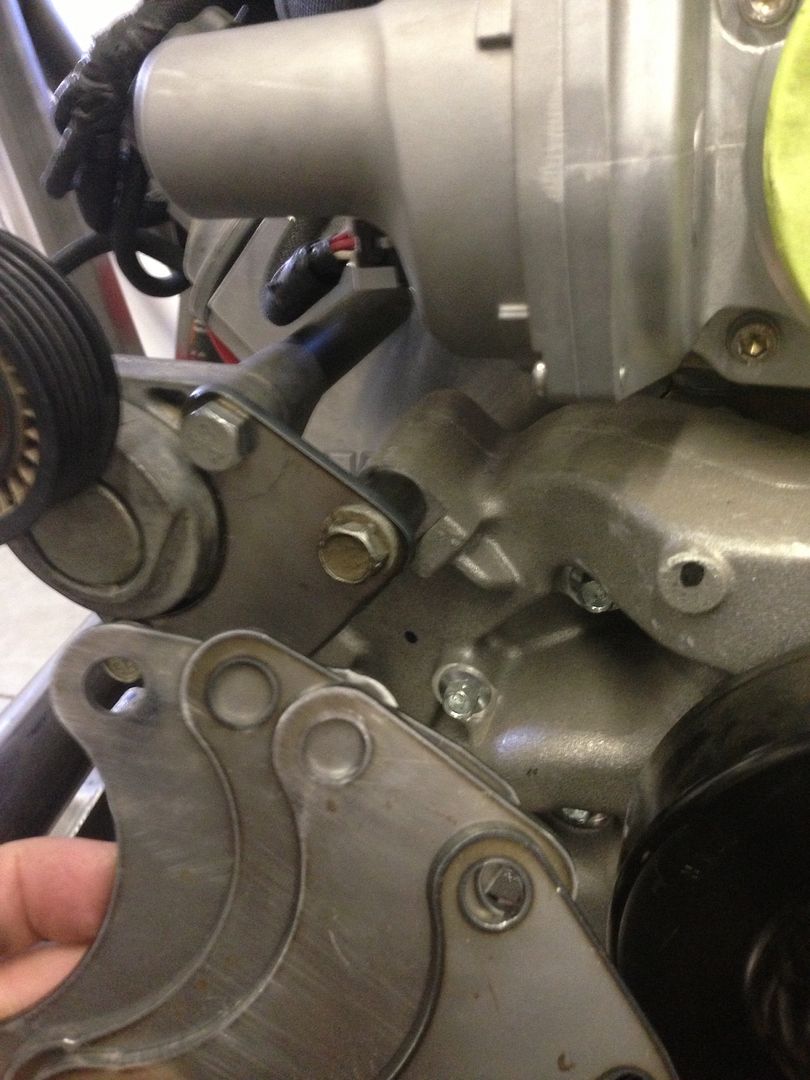

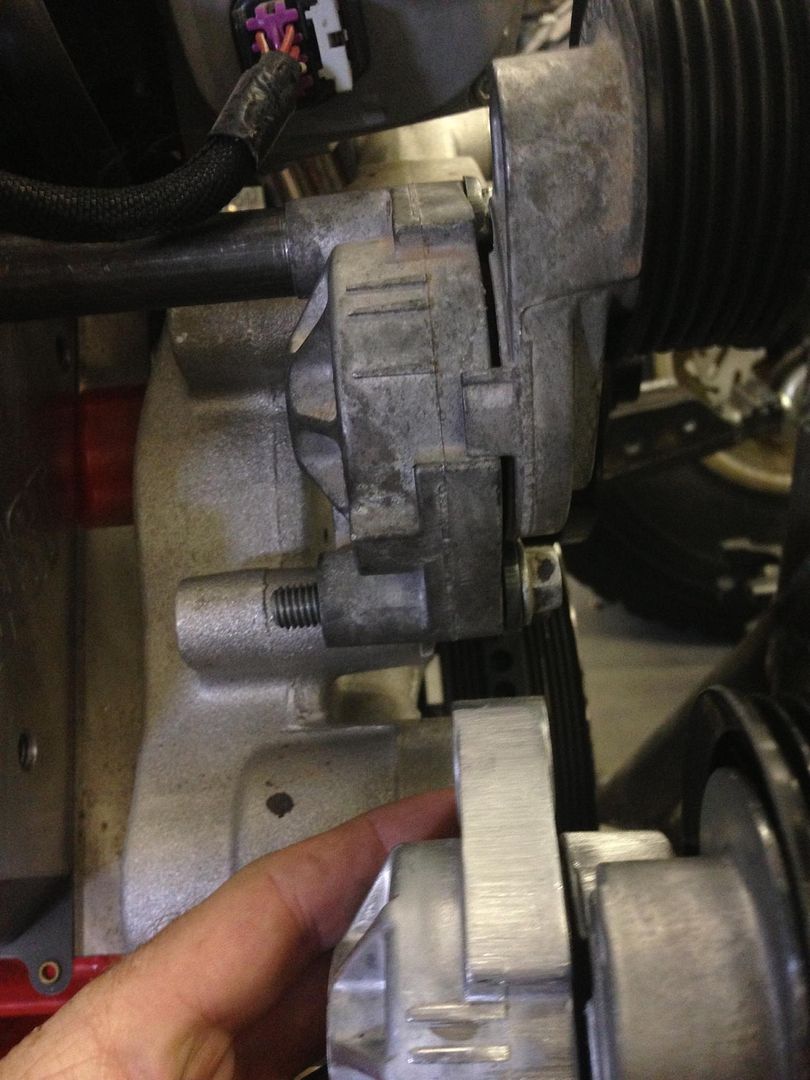

74_Chevota said:Holy fawk...he has alot of time in accessories. Makes you realize how much time the auto makers put into designing all this **** to fit in some of these cars.

laughing1 :afro: :****:

laughing1 :afro: :****: