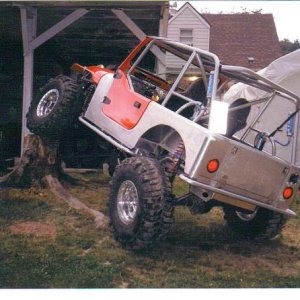

crash2

-Oh no I picked a side-

Rob had a BLAST in the rig--and boy was it a mess :haha:

So being as how I refuse to work on a rig with lumps of dirt/mud falling off I went and cleaned the poor thing up

So being as how I refuse to work on a rig with lumps of dirt/mud falling off I went and cleaned the poor thing up