Wildman1

Well-Known Member

35's busting a HP 60... Makes no sense whatsoever

I'd be really interested to see a pattern and specs after setup. Something is definitely out of whack here. My knee jerk reaction, after seeing the pics, is that maybe the backlash is waaaay too tight.

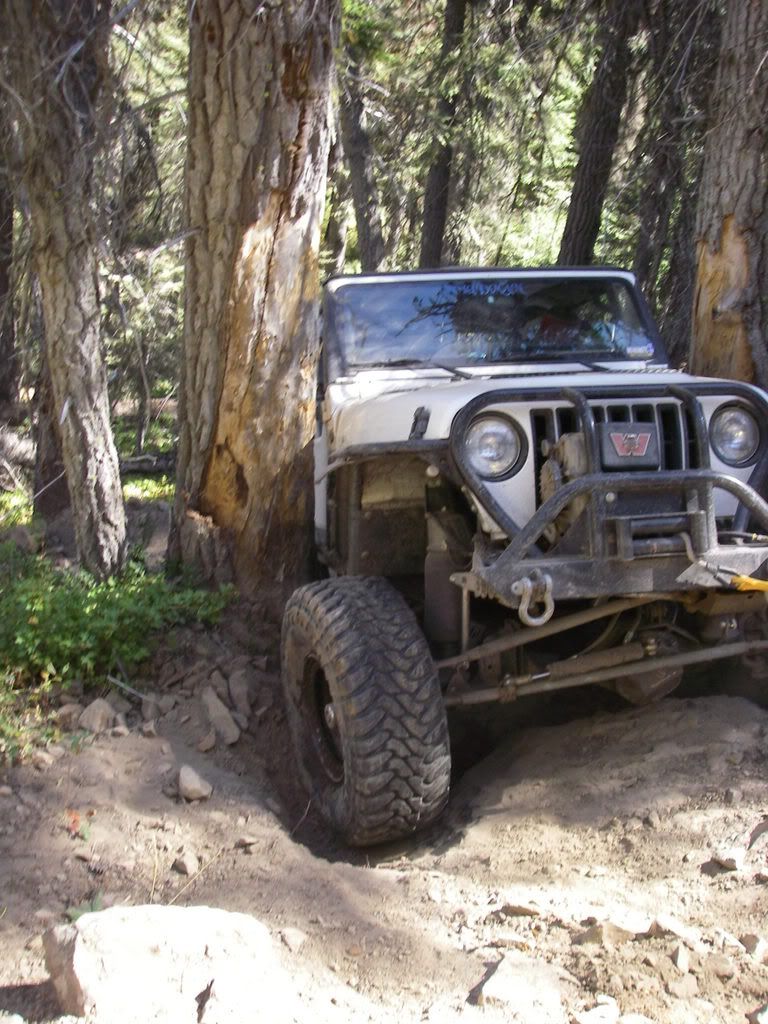

Yep kinda my thoughts too?? :wtf: :wtf: A 35" tire on a axle that they tote as being the shizzel for rockcrawling breaking it. I think I'll call DynoTrac tomorrow.